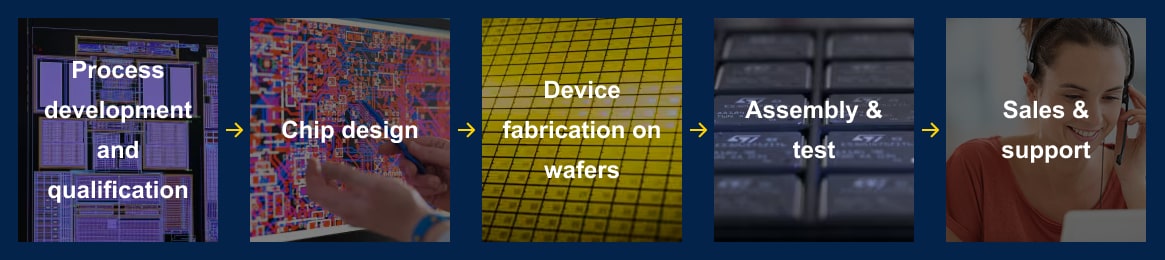

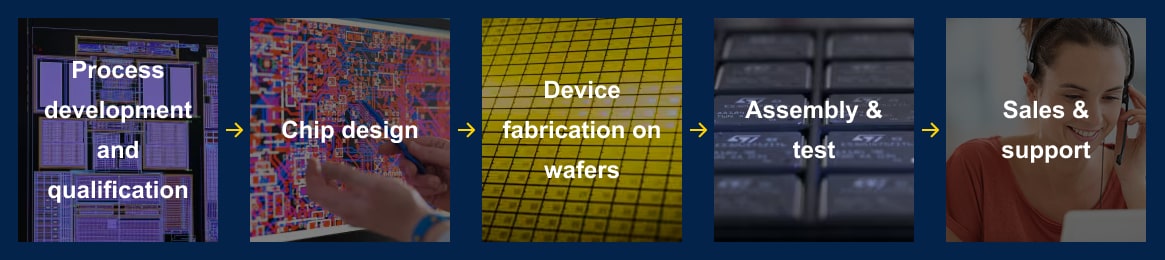

The semiconductor

value chain

Chips. >2B units produced per month.

Fabrication. >300 process steps to complete a chip.

Fab cleanrooms. 1,000x cleaner than hospital operating rooms.

We master the complete value chain to offer our customers the quality, flexibility, and supply security they need.

A sophisticated process

Chip manufacturing involves creating integrated circuits from a semiconductor wafer and testing them before and after integrating them in single packages. It requires advanced technologies and a skillset that only a few companies can master.

The IDM model

We are an integrated device manufacturer (IDM). We design, manufacture, and sell integrated circuits. While some semiconductor companies outsource production to third parties, ST creates the fundamental processes and handles most manufacturing in-house. Being an IDM allows us to tightly integrate our technology and product development with our manufacturing operations while providing our customers the capacity, flexibility, and quality they need.

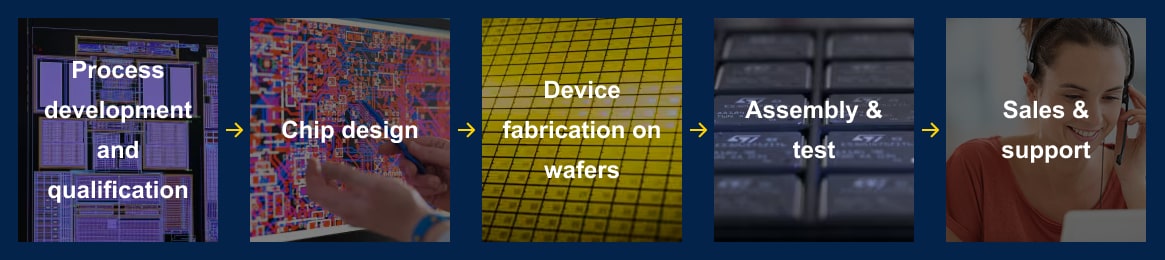

The fabrication of a semiconductor device

Ingot

A mono-crystal of very pure silicon or compound materials grows from melted substance to create a continuous lattice called an ingot.

Substrate manufacturing

Wafer manufacturing consists of creating substrate disks with an extremely flat surface which is suitable for the fabrication of semiconductor devices.

Unprocessed wafer

The ingot is cut into circular disks called wafers. Each wafer is polished and sent to ST’s fabs.

Processed wafer

When fabrication is complete, the processed wafers are tested using electrical patterns.

Front-end manufacturing

The first manufacturing stage consists of fabricating hundreds of miniaturized copies of the same chip design on a wafer.

Die

The wafer is sent to an assembly facility, where it is cut and sorted into functional individual devices each called a die.

Integrated circuit

After a final testing stage, the integrated circuit (IC) is ready to be shipped. ST produces billions of ICs every month.

Back-end manufacturing

Packaging is the second stage of the manufacturing of a semiconductor device, in which every functional die is encapsulated in a supporting case.

Solution creation

ST develops software to support the functionality of the ICs, as well as reference design boards to support customer product development activities.

Substrate manufacturing

Wafer manufacturing consists of creating substrate disks with an extremely flat surface which is suitable for the fabrication of semiconductor devices.

Ingot

A mono-crystal of very pure silicon or compound materials grows from melted substance to create a continuous lattice called an ingot.

Front-end manufacturing

The first manufacturing stage consists of fabricating hundreds of miniaturized copies of the same chip design on a wafer.

Unprocessed wafer

The ingot is cut into circular disks called wafers. Each wafer is polished and sent to ST’s fabs.

Processed wafer

When fabrication is complete, the processed wafers are tested using electrical patterns.

Back-end manufacturing

Packaging is the second stage of the manufacturing of a semiconductor device, in which every functional die is encapsulated in a supporting case.

Die

The wafer is sent to an assembly facility, where it is cut and sorted into functional individual devices each called a die.

Integrated circuit

After a final testing stage, the integrated circuit (IC) is ready to be shipped. ST produces billions of ICs every month.

Solution creation

ST develops software to support the functionality of the ICs, as well as reference design boards to support customer product development activities.

Front-end manufacturing

Front-end manufacturing is the process of fabricating hundreds or thousands of chips on a wafer. It involves hundreds of precisely controlled steps which create millions of transistors and interconnect them using several metal layers. These manufacturing steps are executed on some of the most complex machines in the world. Our factories produce chips on wafers up to 300 mm diameter.

More than

40 km

distance covered by a wafer in the fab during processing

Back-end manufacturing

During back-end manufacturing, also called assembly and test, wafers are cut into separate dice. The dice are embedded in packages that provide all the electrical contacts to connect the component to a circuit board. Final devices, called integrated circuits (ICs), are tested to ensure functionality and reliability. ST ICs are shipped to customers in a wide variety of packages, depending on the size of the products and their intended applications.

Packages

100s

of different package types and variants