Battery Management Systems (BMS) improve the lifecycle, health and safety of power storage systems in electric vehicles

Battery Management Systems (BMS) improve the lifecycle, health and safety of power storage systems in electric vehicles

A BMS measures current, voltage and temperature in critical points of the battery pack and sends that information to an MCU to communicate with other vehicle systems in order to share the state of charge (SoC) and state of health (SoH) estimates for purposes of service.

BMS solution components

With our very flexible kit you can built 3 different BMS topologies (LV single node, centralized access, dual access ring), combining and adding the boards you need to set up your BMS application.

Evaluation board

Battery management system module based on L9963E

Battery management system (BMS) evaluation board that can handle from 1 to 31 Li-ion battery nodes.

Evaluation board

SPI to isolated SPI dongle based on the L9963T transceiver

SPI to isolated SPI dongle used to convert SPI signals in isolated SPI signals

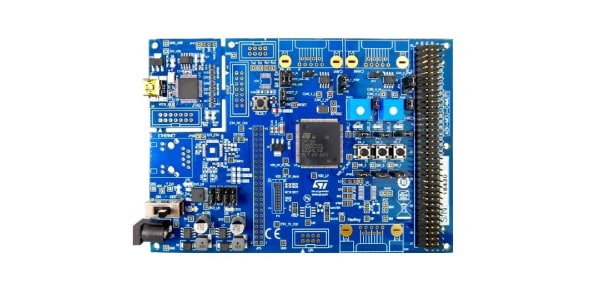

Discovery board

MCU discovery board for SPC5 Chorus 4M automotive microcontroller

Discovery board based on a 4-Mbyte SPC58 automotive microcontroller with CAN transceivers

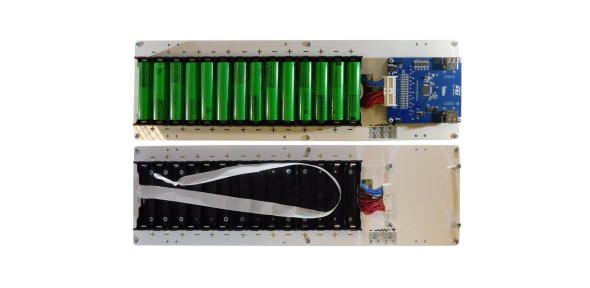

Battery holder

Battery holder for cylindrical batteries and battery management system node

Battery holder for cylindrical batteries and battery management system node for automotive applications

Recommended resources

AutoDevKit Studio for 32-bit PowerPC architecture MCUs

AutoDevKit Studio for 32-bit PowerPC architecture MCUs

Inside the AutoDevKit ecosystem and our development platform STSW-AUTODEVKIT, you can find demos to evaluate the BMS kit in three different configurations.

Each demo software will determine the State of Charge (SoC) and the State of Health (SoH) of the battery pack, allowing efficient cells balancing and extending the battery’s lifespan to enable better performance.

AEK-POW-BMS63EN or the critical art of making battery management solutions more accessible

AEK-POW-BMS63EN or the critical art of making battery management solutions more accessible

If we had to summarize the spirit that drives the AEK-POW-BMS63EN development board in one word, it would be accessibility. Battery management applications are notoriously challenging, and building one…

Getting started with AutoDevKit battery management system (BMS) evaluation kit

For a detailed description on how to use the kit and the related software, please refer to user manual UM3185.

Whitepaper

This whitepaper explores the challenges of designing efficient battery management systems and eliminating consumer range anxiety issues.