Understanding the market and design challenges

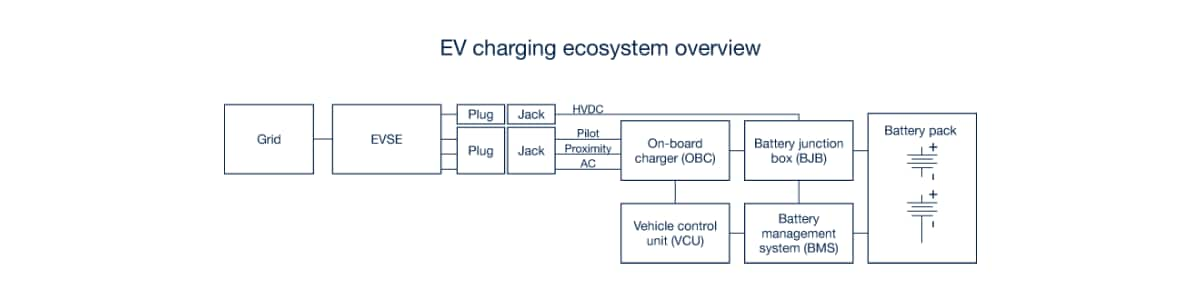

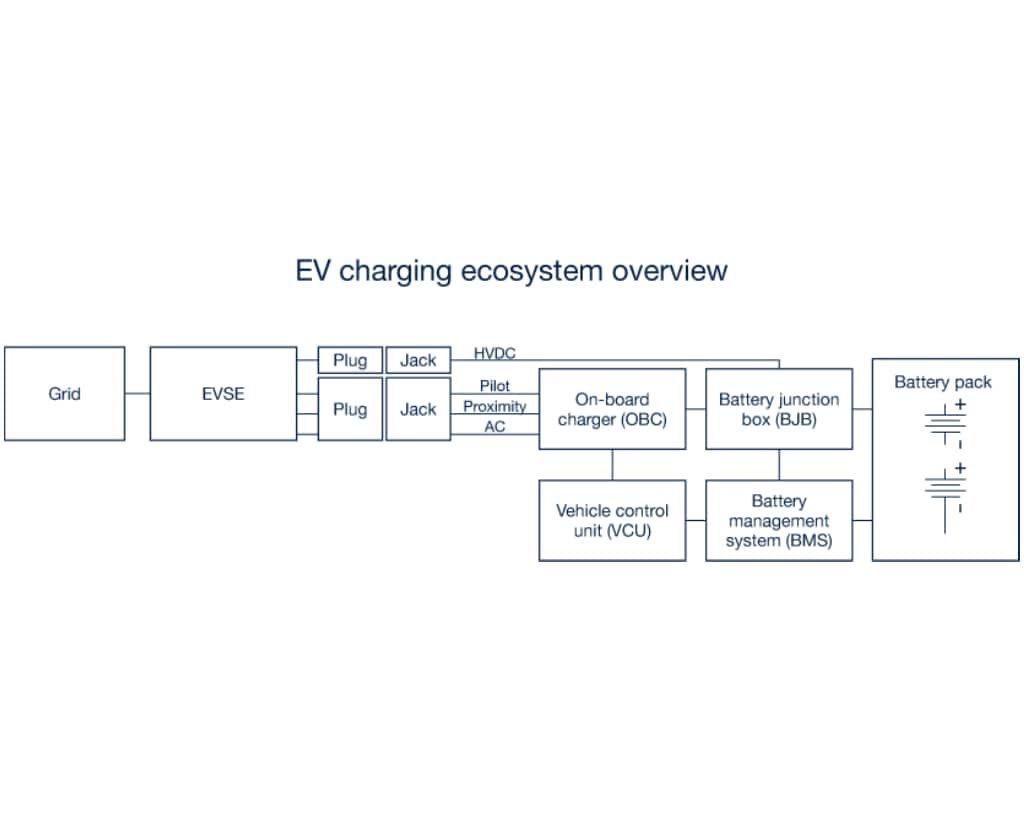

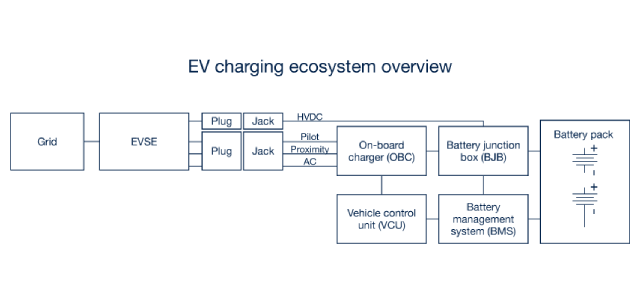

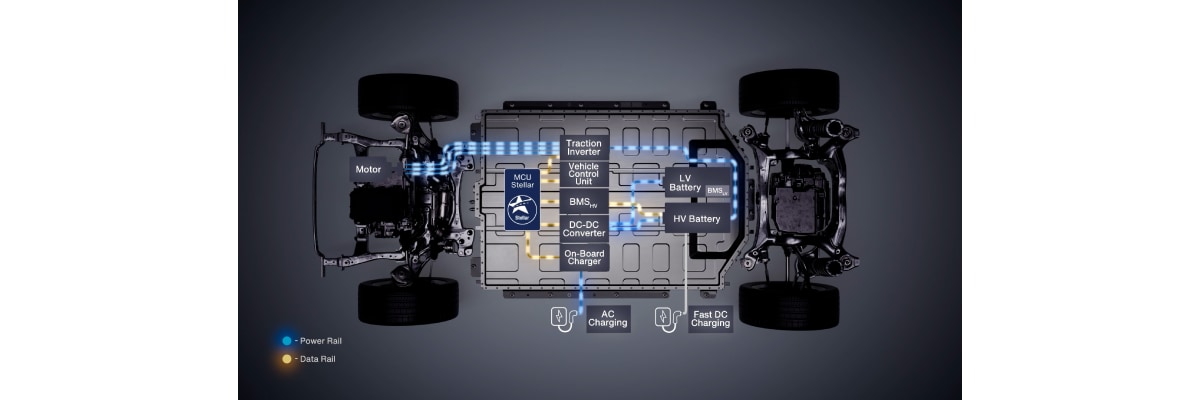

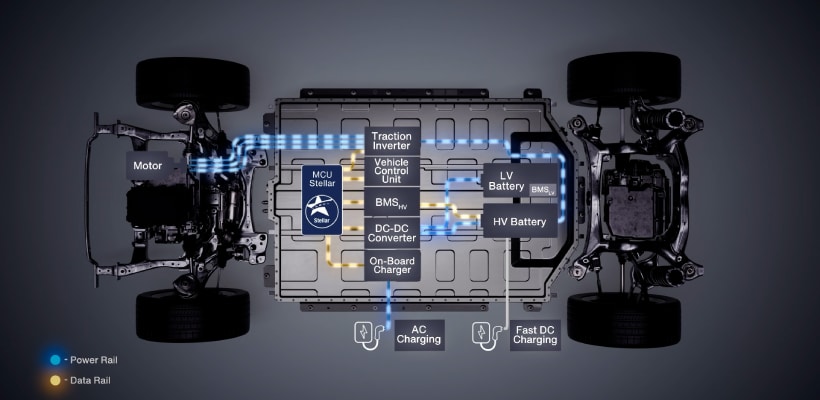

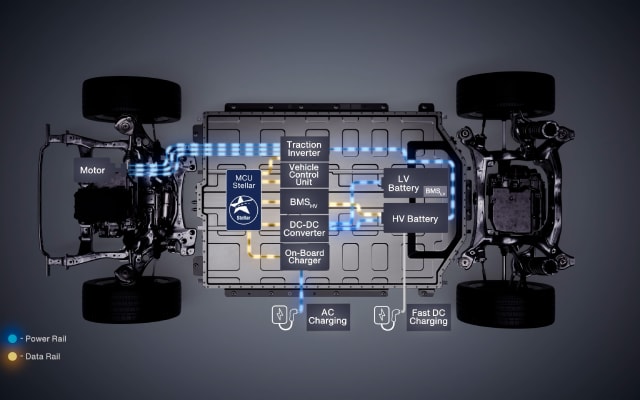

Electric vehicle adoption faces critical challenges such as range anxiety, charging infrastructure limitations, and system cost. The on-board charger is central to balancing charge time, efficiency, and vehicle cost while meeting diverse charging standards. Additionally, the industry is transitioning from traditional centralized vehicle architectures to zonal architectures, which partitions functions spatially rather than functionally to reduce wiring complexity, improve scalability, and enhance system integration – factors that directly influence OBC design and implementation.

Why on-board charging is essential for next-gen EVs and hybrids

On-board chargers – from compact single-phase 3.6 kW units to powerful three-phase 22 kW converters – demand exceptional efficiency and unwavering reliability to support fast charging within tight size and weight budgets. Leveraging deep expertise, ST engineers offer tailored development tools and evaluation kits that simplify overcoming common OBC design challenges.

Our interactive OBC application page highlights key components and solutions for high-performance designs, including voltage, current, and temperature sensing, power factor correction, thermal management, safety, isolation, communication, and smart charging. Explore the page to access design tips and development kits that help optimize overall system efficiency and accelerate your OBC projects.

Discover more on our On-board charger application page.

How ST supports your OBC design journey

Tips for overcoming each challenge

| Resource | Description | Link |

|---|---|---|---|

| Range anxiety and efficiency | Whitepaper | Deep dive into OBC architectures, power ratings, and charging methods. | |

| Power conversion & integration | Webinar | Systems approach to power electronics and MCU control | |

| Highly-integrated scalable designs supporting emerging architectures | Innovative solutions | How ST supports car makers' transformation journey with innovative microcontrollers for automotive | |

| EMI & safety compliance | Application page Automotive portfolio

| Product portfolio addressing EMI filters, transient suppression, and safety solutions. | |

| Standards & communication | Blog post | Practical insights on communication protocols and interoperability. |

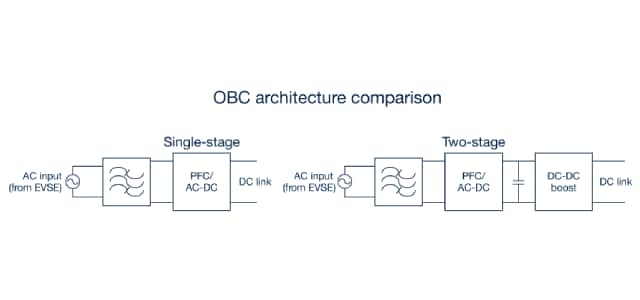

OBC architectures: single-stage, two-stage, and modular designs

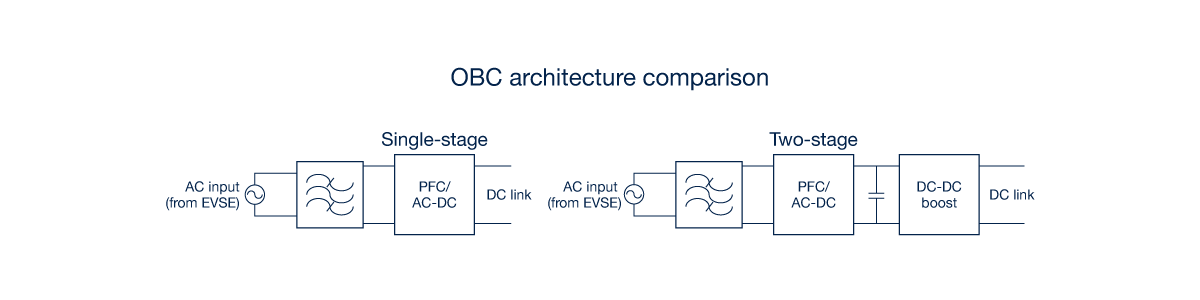

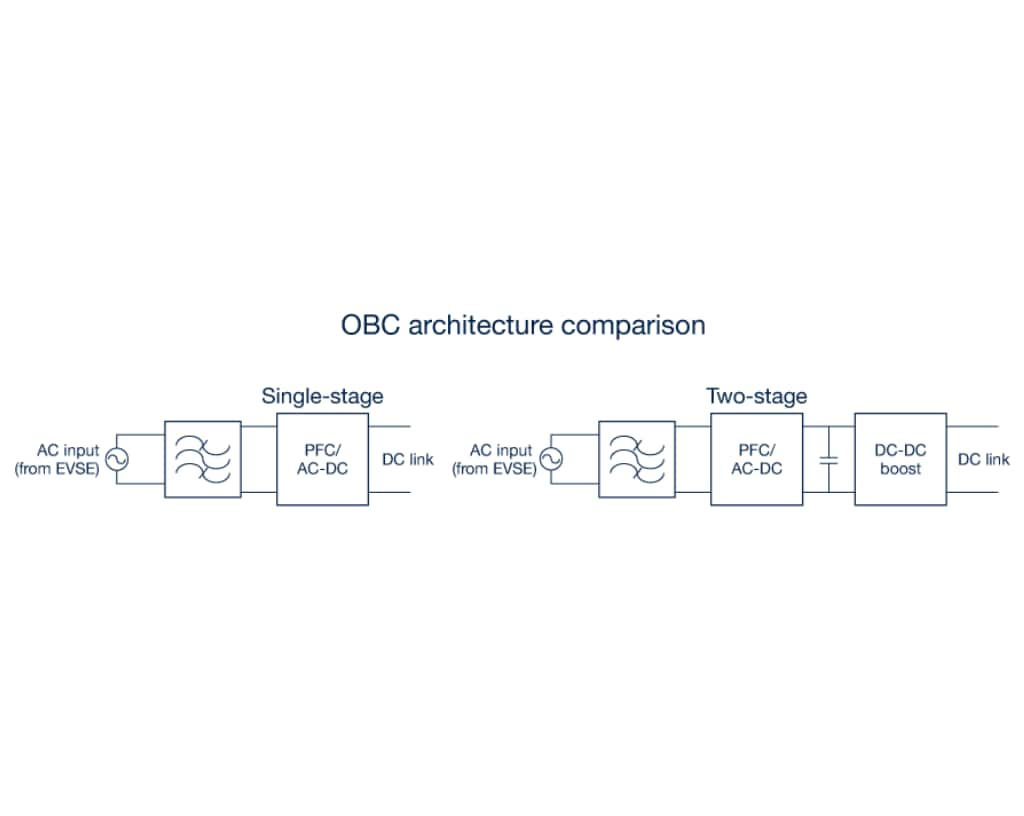

OBC designs vary from traditional two-stage architectures (PFC + DC-DC boost) to innovative single-stage solutions that improve power density and reduce cost. ST supports multiple topologies including Totem Pole and Vienna rectifiers, leveraging wide bandgap semiconductors for efficiency.

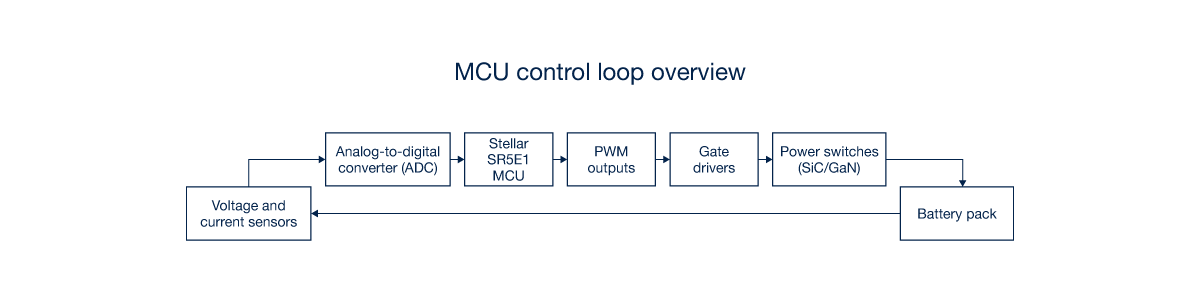

High-performance MCU control for OBC systems

ST’s Stellar SR5E1 MCU offers dual 32-bit ARM Cortex-M7 cores with advanced peripherals like high-resolution timers, ADCs, and PWM units. It supports ASIL-D functional safety, AUTOSAR compliance, and provides the computing power needed for sophisticated control of power electronics in OBCs.

ST’s authority on EV/HEV power systems

Meet John Johnson

Meet John Johnson

With 30+ years in electronics and semiconductors, John Johnson brings extensive expertise in EV and HEV powertrain systems, including on-board charging, battery management, traction, and motor control. His thought leadership guides ST’s innovations for efficient and reliable electrified vehicle solutions.

Tips to reduce your design cycle

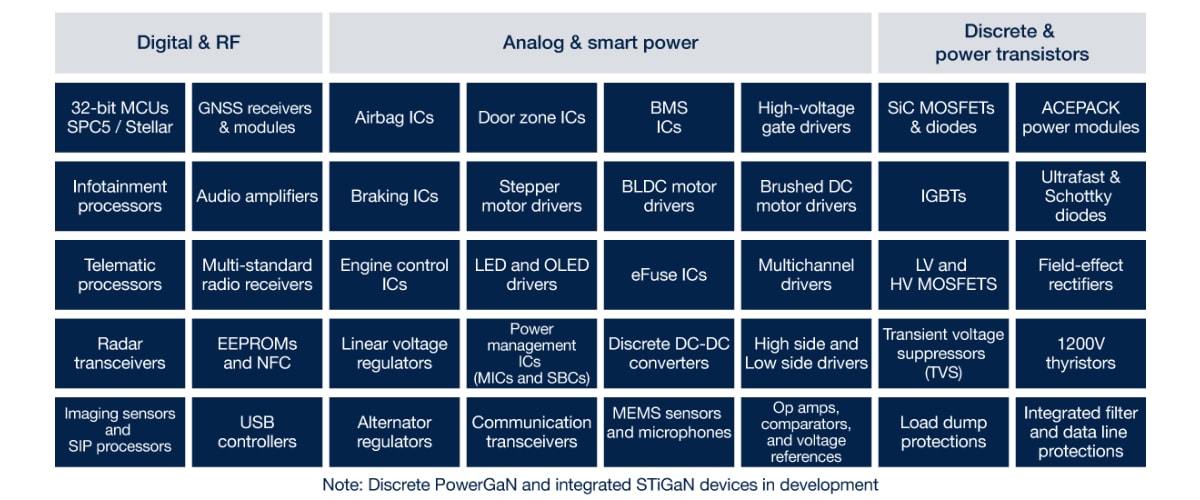

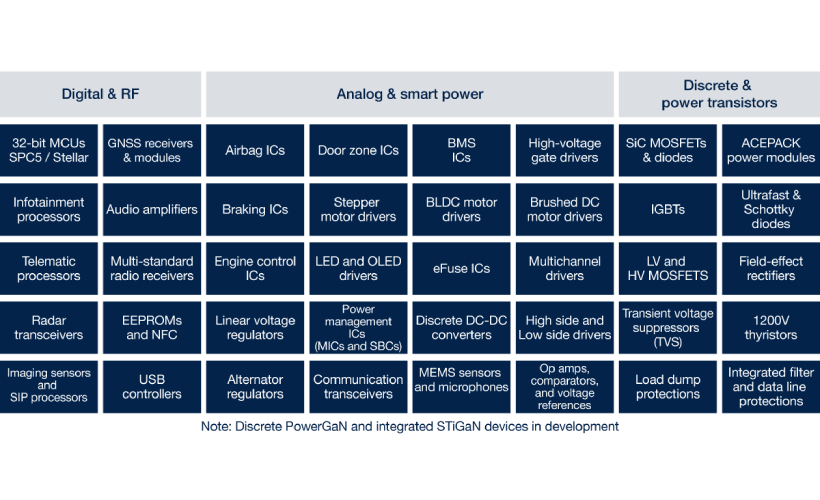

System solutions start with a broad portfolio of products

ST’s extensive portfolio includes a wide range of semiconductors and ICs - covering both automotive- and industrial-grade devices. Importantly, all essential products required for on-board charger system design are available as automotive-grade, ensuring compliance with stringent industry standards.

Below is a comprehensive mapping of these key products across digital, analog, and discrete power technologies to support your OBC development journey.

Select your design’s best match

Key resources to jumpstart your OBC design

Our engineers share essential tips and tools to help you avoid pitfalls and speed up your on-board charger development.

Mobilizing grid power for EVs

Mobilizing grid power for EVs

Whitepaper (by John Johnson)

Discover how ST supports your design efforts with practical, cost-effective solutions aiming at accelerating your development cycle, including our innovative ST OBC/DC-DC converter combo architecture and the key components that make it work efficiently beyond traditional designs.

Demystifying power conversion in e-Mobility

Demystifying power conversion in e-Mobility

On-demand webinar (by John Johnson)

Explore how OBCs, DC-DC converters, and battery management systems integrate to optimize EV powertrains. This webinar covers advanced power electronics, control strategies, and high-performance MCUs tackling complex Lithium-Ion battery management challenges with ST’s innovative solutions for efficient, safe, and reliable electrified mobility.

The 3 challenges plaguing modern on-board chargers

The 3 challenges plaguing modern on-board chargers

Blog post

Discover how ST supports your design efforts with practical, cost-effective solutions aiming at accelerating your development cycle, including our innovative ST OBC/DC-DC converter combo architecture and the key components that make it work efficiently beyond traditional designs.

Optimizing car electrification with ST technologies

Optimizing car electrification with ST technologies

On-demand webinar

Focused on ST’s latest power and packaging technologies, this webinar highlights solutions that enhance thermal management, power density, and functional safety in automotive electrification applications. It showcases integrated module designs and system-level approaches to accelerate development and improve performance in EV charging and power distribution.

Remove or reduce risks related to xEV crash events with fast, reliable HV battery disconnect systems

Remove or reduce risks related to xEV crash events with fast, reliable HV battery disconnect systems

Whitepaper

Two battery disconnect and fire-off solution ICs for a fully integrated or distributed system to remove or reduce the risks related to crash events involving electric vehicles. Our pyrotechnical safety switch systems trigger controlled micro-explosions, cutting the wiring between the HV battery unit and the rest of the vehicle, thus reducing or eliminating the flow of current and risk of electric shock or fire. Full development ecosystem