Reducing anomaly detection time

In condition-based monitoring and predictive maintenance applications, data can be carried out from the smart sensor node or at the gateway, pre-processed or even as raw data, in order to lower power consumption and ensure confidentiality. This allows companies to analyze critical information at node level, reducing anomaly detection time.

Easy development

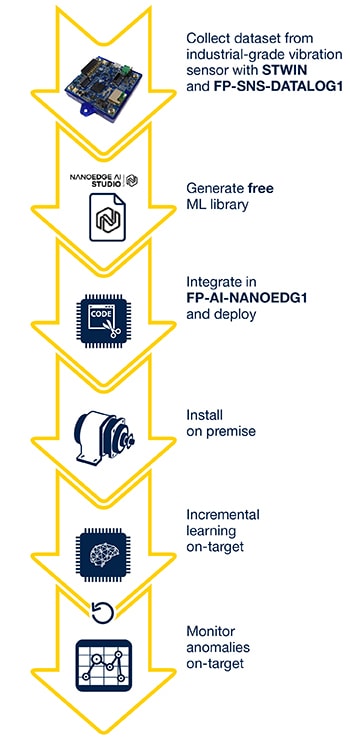

The SensorTile Wireless Industrial Node (STEVAL-STWINKT1B, or STWIN for short) combined with the latest STM32 Cube Software for functions such as High Speed Datalogging (FP-SNS-DATALOG1) and on-device learning based condition monitoring on the edge (FP-AI-NANOEDG1), eases the development of data logging and anomaly detection solutions.

Cover a wide range of use cases in industrial environments

The SensorTile wireless industrial node (STEVAL-STWINKT1B) is based on STM32L4R9ZI ultra-low-power microcontroller (Arm® Cortex® M4 at 120 MHz with 2 Mbytes of Flash memory and 640 Kbytes of SRAM) and embeds industrial-grade sensors, including 6-axis IMU, 3-axis accelerometer and vibrometer for precise movement detection, a very high-frequency digital and analog microphone, as well as high-precision temperature, pressure and humidity sensors to cover the widest possible range of use cases in industrial environments.

The High Speed Data log function pack (FP-SNS-DATALOG1) provides a comprehensive solution to save data from any chosen combination of sensors and microphones up to the maximum sampling rate.

From acquisition to integration

FP-AI-NANOEDG1 covers the entire design of the Machine Learning cycle, from data set acquisition to the integration of NanoEdge™ AI Studio generated libraries on a physical node.

Optimized for condition monitoring and anomaly detection, it manages sensor input data collection, on-device learning sessions and inference models in real-time on an STM32L4R9ZI ultra-low-power microcontroller.

Discover how our customers have been using our tools