Launch. 2020 world's first Lab-in-Fab.

Solutions. 8" piezoelectric platform.

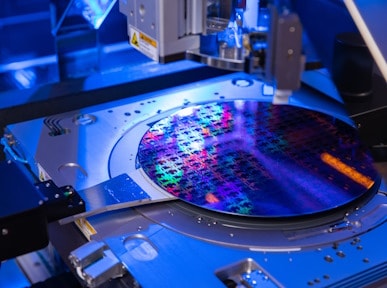

Fab. >2000 m² of cleanroom serving Lab-in-Fab.

Showcase your ideas and win a slot in the next multi-project wafer shuttle at Lab-in-Fab.

Innovative student challenge: piezoelectric MEMS design contest update

Innovative student challenge: piezoelectric MEMS design contest update

Thank you to all the innovative students who submitted their design ideas for cutting-edge piezoelectric MEMS devices. The submission period is now closed.

What’s next?

- Abstract review: Ongoing since December 15th, 2025

- Finalist pre-notification: Starting January 12th, 2026

- Award ceremony: During the IEEE MEMS 2026 International Conference (January 25th to 29th, 2026)

Watch the full replay of the September 18th webinar to learn more about Lab-in-Fab, the challenge and its objectives.

Stay tuned for updates on the finalist announcements. We look forward to celebrating the innovative ideas at the award ceremony.

Lab-in-Fab: advancing piezo MEMS technology

Lab-in-Fab: advancing piezo MEMS technology

The Lab-in-Fab is an R&D line focused on piezo MEMS technology within ST’s manufacturing facility in Singapore. The world’s first of its kind, it unites three partners with complementary expertise in piezo materials, MEMS technologies, and wafer-fab tools.

In collaboration with A*STAR research institute and Japanese tool vendor ULVAC, we combine R&D and high-volume manufacturing to accelerate concept development. Customers benefit from integrated theoretical and practical expertise, boosting innovation and speeding up new materials, processes, and product development.