Edge processing

Smart sensor nodes

Condition Monitoring vs Predictive Maintenance

Condition Monitoring (CM) is the monitoring of several parameters such as equipment vibration and temperature to identify potential issues such as misalignments or bearing failures. Condition monitoring tools can for instance map equipment degradation when a vibration analysis shows a change in the harmonic frequency of rotating equipment components. Frequency analyses can be based both on vibrometer and microphone data.

Continuous Condition Monitoring techniques can be applied on several pieces of equipment such as compressors, pumps, spindles and motors and can also be implemented to identify partial discharge on machine or vacuum leaks.

Predictive Maintenance is based on Condition Monitoring, anomaly detection and classification algorithms, and integrates predictive models which can estimate the remaining machine runtime left, according to detected anomalies. This approach uses a wide range of tools, such as statistical analyses and Machine Learning to predict the state of the equipment.

The importance of Edge Processing

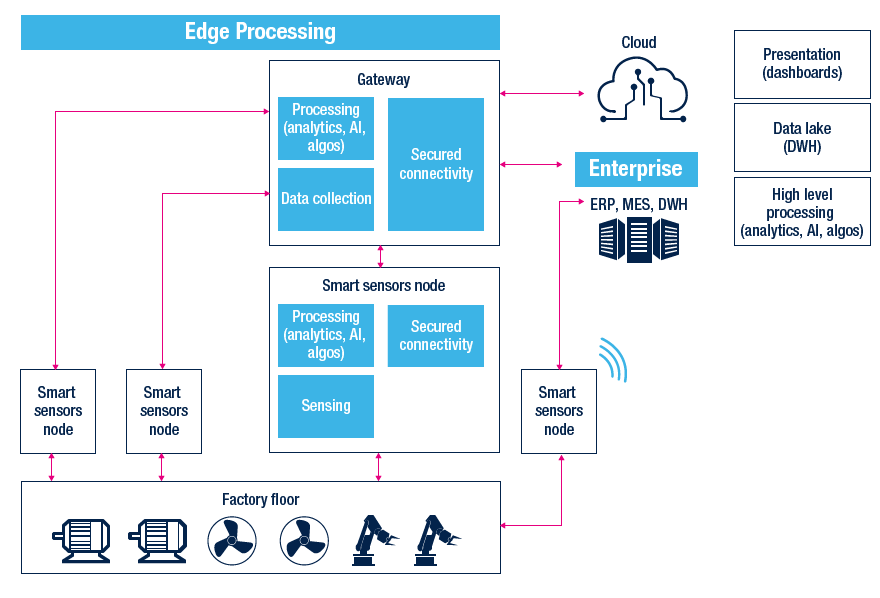

From designing smart sensor nodes and configuring embedded software running in sensor nodes and the gateway, to developing software to be integrated in the Cloud or company Enterprise Resource Planning (ERP) system, Predictive Maintenance requires a variety of skills and competencies. Machine Learning and Artificial Intelligence algorithms can be implemented to ensure technical anomalies are detected early and equipment uptime is maximized.

Smart sensor nodes are key enablers of predictive analysis. They gather and log pre-processed, secure data to be displayed in visualization tools and used in other processing algorithms. Smart sensor nodes can also process data and detect anomalies by reducing computational latency. For example, smart sensor nodes can detect a small rise or a sudden increase in temperature indicating a probable device issue and future reliability problems.

Gateways are either implemented to collect and process data from several smart sensor nodes or to act as a connectivity bridge to enable secure connection to the cloud using ethernet, Wi-Fi, cellular or LPWAN technologies.

Edge processing combines and distributes processing power among smart sensor nodes and gateways with the aim of sending the right data at the right time to enterprise-level systems where more advanced analyses can be performed. Processing at the Edge can also use Machine Learning and Artificial Intelligence (AI) algorithms to enhance smart sensor node and gateway mission profiles and to broaden the scope of anomaly detection and classification.

ST's portfolio for Condition Monitoring and Predictive Maintenance

Condition Monitoring and Predictive Maintenance are value-added yet challenging applications in Industry 4.0. ST has therefore deployed advanced ICs and an ecosystem of evaluation tools, software, documentation and online dashboards for remote monitoring, which are continuously updated to be in keeping with industrial needs.

Microcontrollers and microprocessors

STM32 Arm® Cortex® M4/M33/M7-based microcontrollers and STM32 Arm® Cortex®-A7® microprocessor series with floating points capabilities can process sensor data at the edge. The STM32Cube.AI toolchain allows users to implement Neural Networks and Machine Learning for a deep learning approach.

Sensors and Inertial Measurements Units (IMU)

ST also offers high-performance, cost-competitive sensors and Inertial Measurement Units (IMUs) with a 10-year supply guarantee (longevity program), including accelerometers and ultra-sound analog microphones enabling vibration analysis from simple Pass/Fail monitoring to high-accuracy, frequency-based data analysis. Our portfolio also includes a wide range of environmental sensors for temperature, humidity and pressure sensing and advanced MEMS sensors containing digital functions optimized to run Machine Learning algorithms that allow the data processing to be shared between the IMU and the host processor.

Wired and wireless communication solutions

A range of wired and wireless communication solutions complement our offer: IO-Link-compatible devices for industrial wired connectivity, and a portfolio of wireless technology such as Bluetooth Low Energy (BLE) SoCs and network processors, as well as LPWAN SoCs and transceivers supporting LoRa, Sigfox and license-free ISM and SRD frequency bands.

Together with our partners to help with your challenges

Predictive Maintenance is a key challenge for the industry and the necessary skills to implement these techniques may not be easy to find or acquire. We have therefore brought together an ecosystem of trusted Authorized Partners to support our customers in the tailored design and implementation of their solution. To find out more, visit our Partner page and our Tools and Software section on st.com.

Anomaly detection and AI: one step closer to ST intelligent sensors

Moving from condition based monitoring based on sensors data to anomaly detection computed inside the sensors represents a major innovation in predictive maintenance for industrial applications and offers significant advantages in system-level power efficiency, downtime reduction, and maintenance costs.

Learn moreFeatured Videos

From Condition Monitoring to Predictive Maintenance