Monitoring quality in a food production line

Create an AI model that predicts the quality of processed food instead of measuring it.

Approach

The goal was to predict roasting quality based on different variables.

The roasting machine consists of 5 chambers containing 3 temperature sensors each. There are also sensors used to measure the layer height and the humidity of the raw material entering the machine. So, 17 sensors in total.

In this example, the quality is measured in a laboratory. The AI model will use examples to understand the relationship between the sensor values and the quality measured. This replaces the manual steps that take place in the laboratory to gain time.

The dataset contains sensor data recorded every minute (from all 17 sensors), and a quality value determined each hour. For simplicity, we only look at the sensor data that precedes the quality measurement. Another approach would be to concatenate all sensor measurements.

We then used NanoEdge AI Studio to create an Extrapolation project that can predict the quality of the roasted goods based on the data from the 17 sensors every hour.

Sensor

Data

Signal length 17 (multi sensors)

Data rate every hour

Results

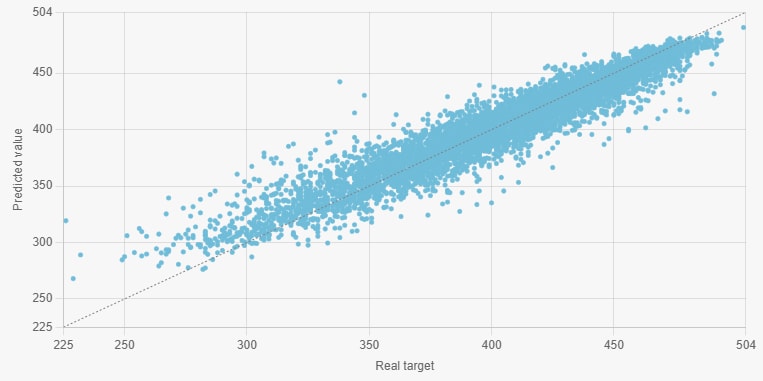

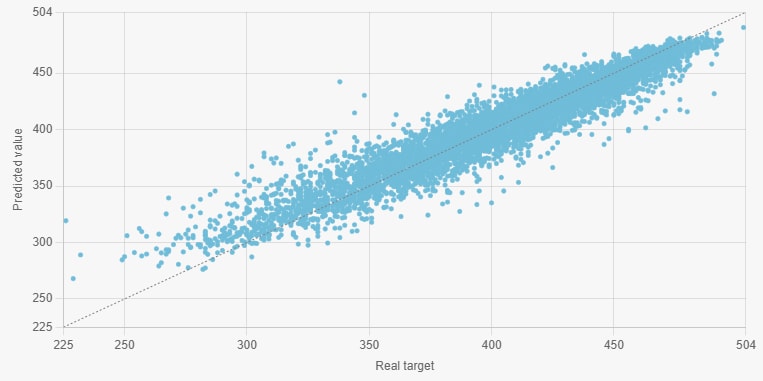

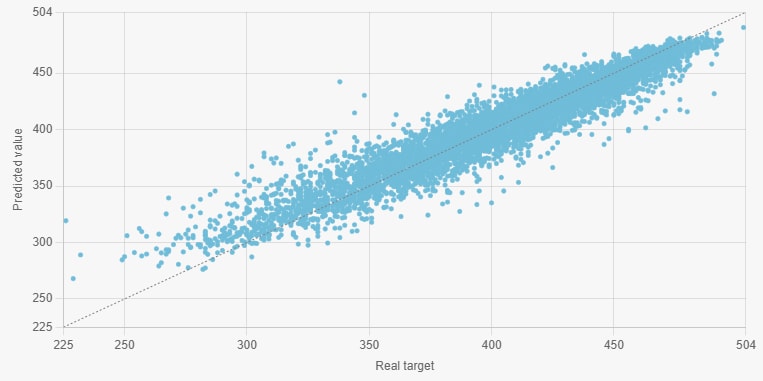

Extrapolation:

90.81% accuracy, 0.1 Kbytes of RAM, 189.8 Kbytes of Flash memory

Resources

Model created with NanoEdge AI Studio

A free AutoML software for adding AI to embedded projects, guiding users step by step to easily find the optimal AI model for their requirements.

The STM32 family of 32-bit microcontrollers based on the Arm Cortex®-M processor is designed to offer new degrees of freedom to MCU users. It offers products combining very high performance, real-time capabilities, digital signal processing, low-power / low-voltage operation, and connectivity, while maintaining full integration and ease of development.