Forging presses are critical assets in heavy industry, but unexpected failures can lead to weeks or even months of costly downtime. To secure continuous production, ALTEN leveraged edge AI technologies to anticipate deviations and prevent failures before they occur.

Approach

On a shop floor with presses exceeding 900 tons and producing over 1,000 pieces daily, a single technical problem can result in up to three months of downtime and significant revenue loss. Breakdowns stem from raw material issues, aging equipment, or unexpected wear and tear.

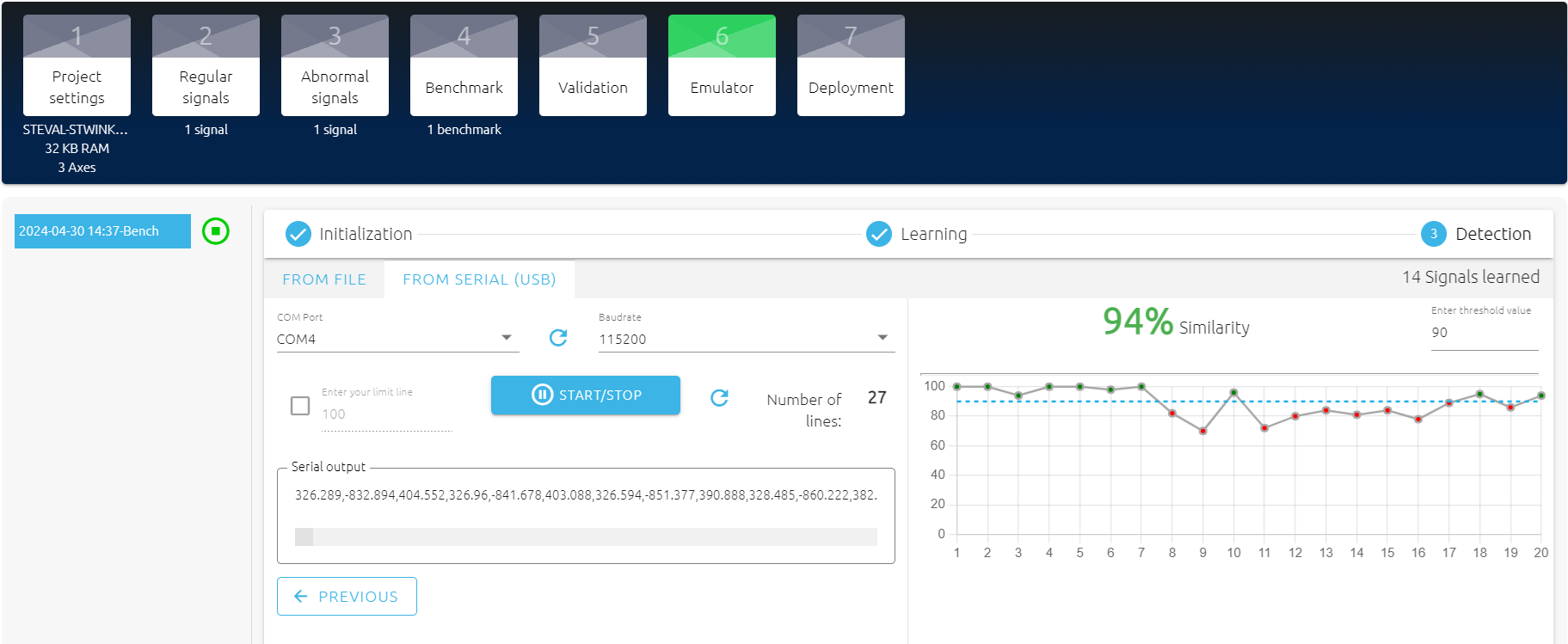

To address this, smart sensors were installed at various locations on the press to identify the optimal spot for monitoring. Using NanoEdge AI Studio, the system learns the press’s normal behavior and categorizes potential breakdowns.

Experiment with two types:

- Learning to normality (anomaly detection)

- Categorizing breakdowns (n-Class categorization)

Result of the experiment: successful detection of all breakdowns across different presses and types of breakdowns.

Both effective anomaly detection and n-Class categorization were successfully achieved thanks to NanoEdge AI Studio.

Next steps:

Automate early warnings with varying severities, enabling targeted maintenance such as disassembling only the affected part (e.g., the matrix) when pieces are stuck due to excess raw material. The sensor system can distinguish several fault levels, providing alerts to prevent breakdowns or halt production to avoid scrap.

Sensor

Author: Alten | Last update: June, 2025

Resources

Model created with NanoEdge AI Studio

A free AutoML software for adding AI to embedded projects, guiding users step by step to easily find the optimal AI model for their requirements.

The STM32 family of 32-bit microcontrollers based on the Arm Cortex®-M processor is designed to offer new degrees of freedom to MCU users. It offers products combining very high performance, real-time capabilities, digital signal processing, low-power / low-voltage operation, and connectivity, while maintaining full integration and ease of development.