Space ASIC

Rad-hard and rad-capable technologies

ST has an established expertise in radiation-hardened, application-specific ICs (ASICs) for the space industry. We offer complete space technology platforms including libraries, IP, tools, and methods developed by our experts in radiation hardening. We also propose differentiated radiation-capable technologies such as CMOS mixed signal, SiGe, power, and integrated passive devices to selected ASIC and foundry customers.

Our ESCC- and QML-certified facility in Rennes (France) is central to our space and hirel supply chain. Our network of partners ensures that customers can find comprehensive support during solution development, prototyping and production phases. The offer primarily addresses the ASIC requirements for prime contractors, payload and subsystem suppliers, as well as foundry with services (Foundry+) for fabless chip makers developing ASSP and standard products.

Rad-hard technologies

Rad-hard technologies include dedicated rad-hard libraries and hard IP, and may also involve specific tools and hardening methodologies.

Rad-capable technologies

Rad-capable technologies have intrinsic features that allow the development of rad-hard products 'by design', as proven through theoretical analysis, specific radiation tests, and flight history.

High-volume manufacturing in proprietary wafer fabs with proven quality and longevity.

Our portfolio

| Technology | Scope | Key features | Status |

|---|---|---|---|

| 28 nm FD-SOI | Digital, analog, RF | Available rad-hard platform and rad-hard IP | Flying LEO, GEO |

| 65 nm | Digital, analog | Available rad-hard platform and rad-hard IPAvailable rad-hard platform and rad-hard IP | QML-V Flying GEO |

| BiCMOS55X | RF, digital | fT=385 GHz – fMAX=500 GHz | Flying LEO |

| BiCMOS9MW | RF, digital | fT=220 GHz – fMAX=280 GHz | Flying LEO |

| HCMOS9A | Digital, analog | | Flying GEO |

| BCD6s SOI | Power ICs | Up to 190 V | Flying GEO |

| Integrated Passive Device | RF filters | | Flying GEO |

| CMOS | Image sensors and readout integrated circuits (ROICs) | Large pixels, IR, front-side illumination (FSI), back-side illumination (BSI), stitchingLarge pixels, IR, front-side illumination (FSI), back-side illumination (BSI), stitching | Flying GEO |

Our portfolio

Digital, analog

Available rad-hard platform and rad-hard IPAvailable rad-hard platform and rad-hard IP

QML-V Flying GEO

Image sensors and readout integrated circuits (ROICs)

Large pixels, IR, front-side illumination (FSI), back-side illumination (BSI), stitchingLarge pixels, IR, front-side illumination (FSI), back-side illumination (BSI), stitching

Flying GEO

ST’s hardening expertise

In more than 45 years, we have acquired unique expertise in the development of a wide variety of products hardened by design, by process, or using dedicated libraries and hardened macrocells for space, communications, and automotive applications.

Pioneers.

45+

years of experience in hardening

Robust.

1,000+

rad tests on cells and chips

Reliable.

100+ billion

cumulative flying hours without failure

Proprietary tools and methods

Thousands of radiation tests of various technologies and products have led to the development of proprietary tools and methodologies. These tools are fully deployed in ST’s 65 nm and 28 nm FD-SOI rad-hard libraries. They allow performance, power dissipation, and die size optimization based on specific mission profiles.

Proprietary tools and methods*

- Radiation sensors

- TID-aware aging models

- Multiscale fault injection simulator

- SEU Montecarlo code

- Ultraselective hardening (CPU, SoC)

Rad-hard IP and libraries*

- SERDES, ADC, DAC, PLL

- Arm®: A53, R52 rad-hard macrocells

* deployed for space in 65 nm and 28 nm FD-SOI

Space packaging and qualification

ST proposes a complete supply chain through its ASIC production and Foundry+ offer.

Produced in Europe

All ‘traditional space’ products are assembled in ST’s ESCC- and QML-certified facility in Rennes (France). The assembly using standard plastic packages supporting 'new space' requirements is performed in both Asian and European facilities..

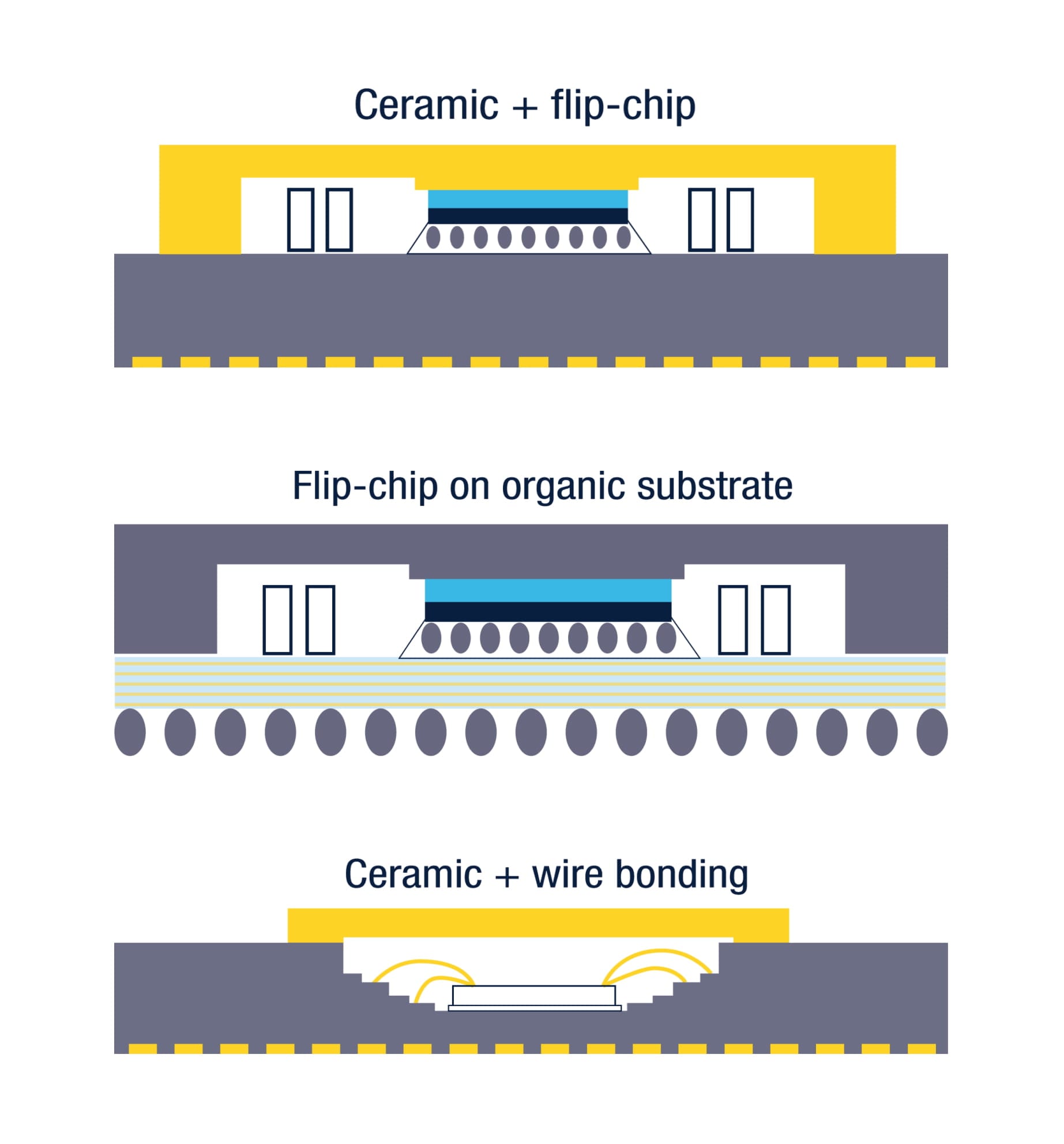

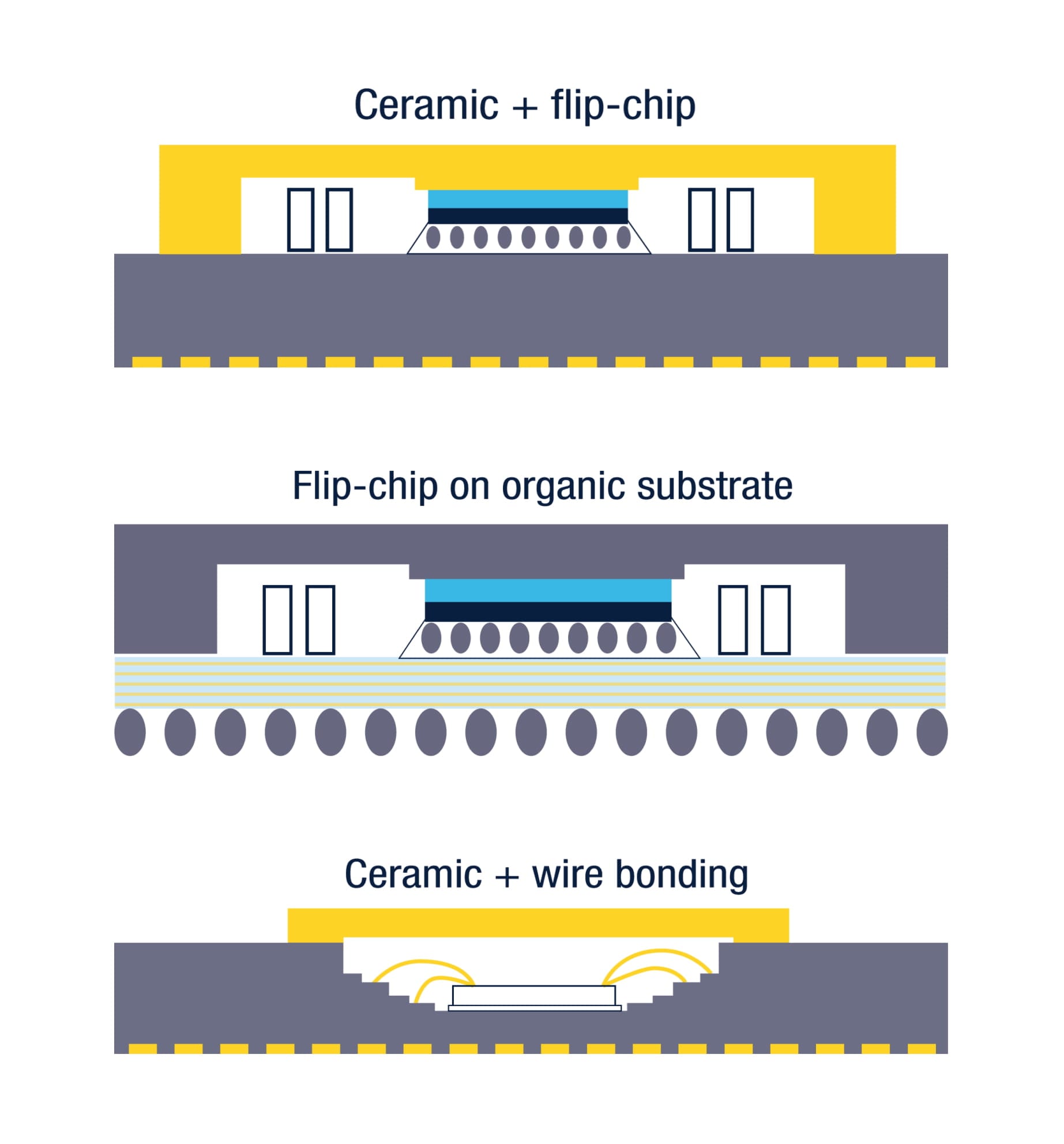

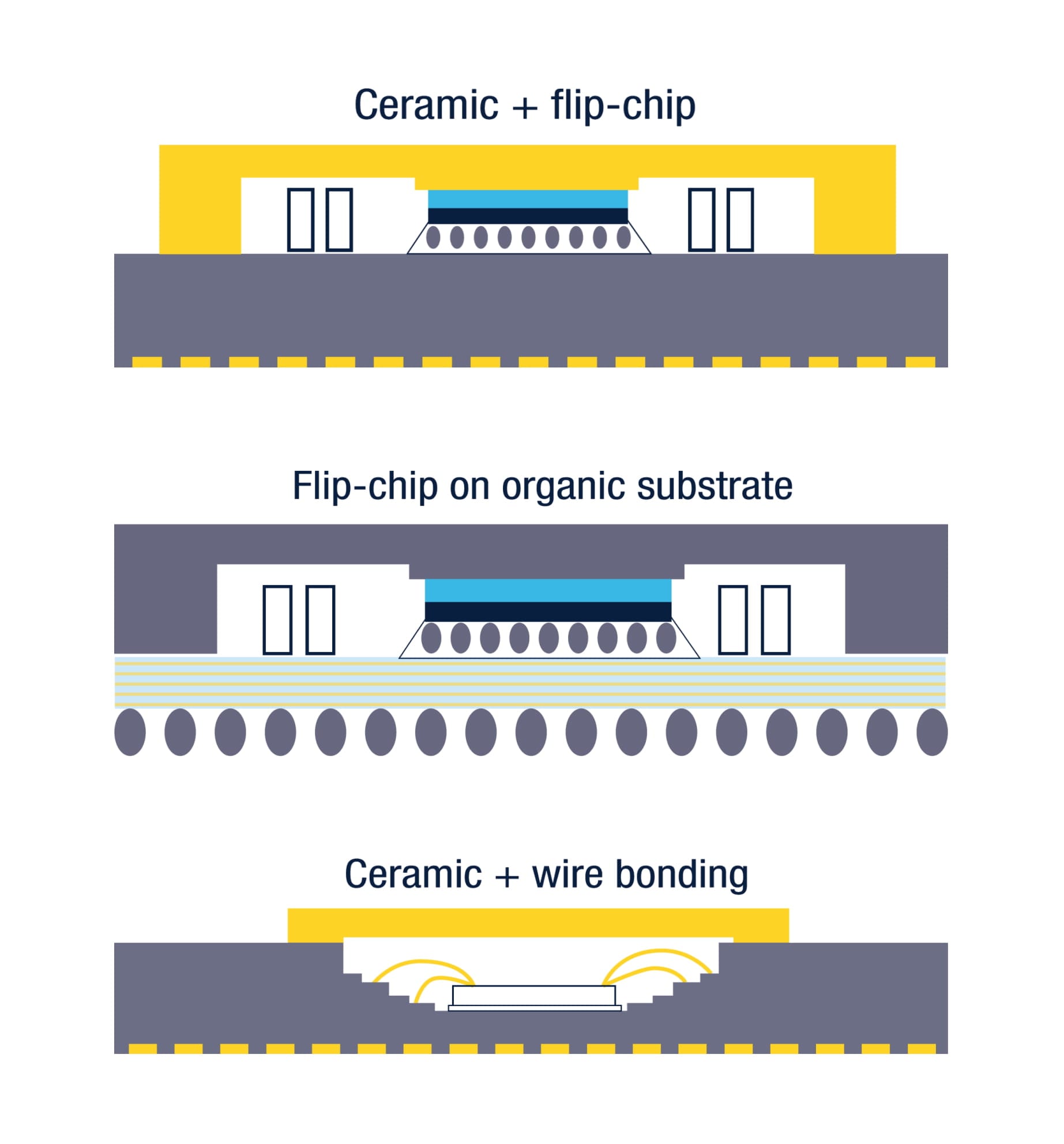

Advanced packaging for space ICs

Our facility in Rennes offers both flip-chip and wire bonding assembly capabilities. Recently updated, the flip-chip line is compatible with ceramic and organic substrates for traditional or new space applications. This enhanced line includes top-side cooling package options for better thermal management and can support low to medium quantities. We also upgraded our legacy wire bonding line for hermetic ceramic packages to increase our capacity and allow higher density ASICs up to CQFP352 and CLGA625.

Quality assurance

ST has developed a high degree of expertise in space quality assurance over several decades of involvement in space products and technologies, which is demonstrated by its unique triple ESCC, QML, and JAN certification. This expertise allows us to extend our certified capability domains to technologies and packages required for the most advanced space ASICs and ASSPs.

Space ASIC and Foundry+ customers can benefit from our ESCC and QML capability domains to achieve formal agency qualification or customized qualification tailored to specific mission profiles.

Value-added services, working models, and ecosystem

Technologies like 28 nm FD-SOI, 65 nm CMOS, and 130 & 55 nm BiCMOS (SiGe), are highly suitable for new developments. Some design houses have already used them to develop rad-hard components for space applications. ST is extending such support to other rad-capable technologies proposed for space ASICs and Foundry+.

Most of these technologies qualify for ST’s low-cost prototyping and multiproject wafer (MPW) services, although some restrictions may apply.

ST proposes different levels of contribution and added value, from a pure foundry model to pure ASIC.

Learn more about our products for space applications.

Rad-hard products for space applications

Discover ST's comprehensive ecosystem of products and services for traditional and new space

Networking technologies for deep space

TTTech and ST collaborate to provide high-performance networking solutions for deep space

Rad-hard solutions for ‘New Space’

ST releases economical radiation-hardened ICs for cost-conscious ‘New Space’ satellites