We respect the planet

Water. 54.6%* total recycled and reused.

Waste. 97%* diverted from disposal.

Energy. 84%* renewable electricity adoption.

We commit to mitigating our impact on the environment and reaching carbon neutrality by 2027.

Our first environmental report was issued in 1998...

And it set our vision to be

recognized as a leader in

environmental care.

Water

Optimizing our water management

For over 3 decades, we have adopted a comprehensive management approach that includes water stress assessment, conservation programs, water efficiency as well as wastewater treatment before discharge in the natural environment.

Waste

Striving for zero waste and promoting circular economy

Our waste management strategy is based on the proper classification, separation, and safe disposal of waste. This waste includes hazardous substances, metals, packing, plastics, effluents and other nonbiodegradable materials. Wherever possible, we give priority to reduction, reuse, recycling and recovery over incineration and landfill.

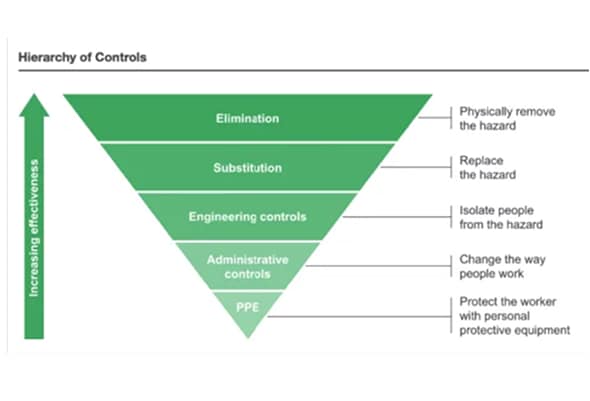

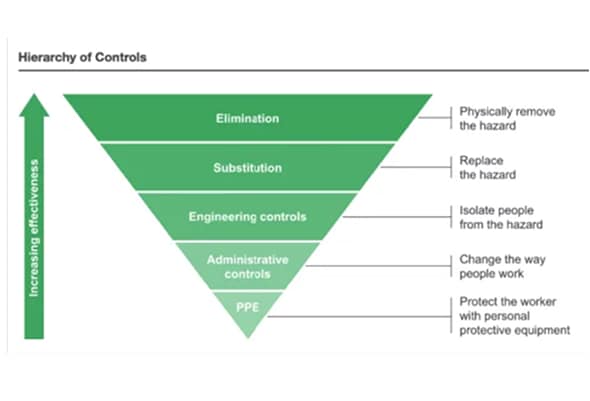

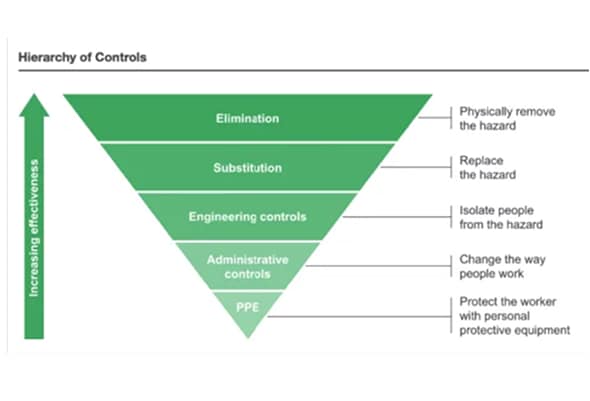

Chemicals

Reducing and substituting chemicals

We are committed to zero hazardous waste in landfill, using innovation to replace hazardous materials and to identify reuse and recycling whenever possible.

We also conduct regular internal Environment, Health & Safety (EHS) audits and risk assessments, as we work to anticipate upcoming legislation.

Contributing to the UN Sustainable Development Goals (SDGs)

The Sustainable Development Goals (SDGs) set by the United Nations define global sustainable development priorities and aspirations for 2030, highlighting the world’s biggest social and environmental challenges. As a multinational company, we are convinced we have a responsibility and a role to play to help achieve these goals.

We have mapped the 17 SDGs to our material topics, sustainability programs and business strategy. We have identified the 11 goals that are most relevant to our sustainability strategy.