Gearbox fault detection using vibrations

Vibration analysis to detect an abnormal behavior on a gearbox.

For example, before an anomaly or a failure occurs, your machine generates slightly abnormal vibration patterns. By placing a sensor on the machine, we can monitor its activity, and thanks to Machine Learning, we can identify the system's normal functioning pattern. By analyzing the evolution of vibrations, we can detect any changes, which may be caused by aging or an anomaly. Gearboxes can be very complex and expensive systems. In order to avoid any malfunctioning and to optimize the frequency of the system's maintenance, we have implemented ML-based anomaly detection, which is the first step towards a predictive maintenance application. This approach can easily be adapted to many industrial machines.

Approach

The dataset was made using four vibration sensors placed in different directions on a gearbox test bench.

In this example, we are using 2 files of the dataset. One for a healthy gearbox, one for a broken one.

We are using a constant load of 50% but the same results are also reached with various loads.

Sensor

Data

>> Link to the original page of the dataset

>> Download the dataset used in the NanoEdge AI Studio

Regular and Abnormal signals

- Regular signals: Normal functioning

- Abnormal signals: Faulty gear

Signal length 512 (4 axes)

Data rate 416 Hz; Range: 2g

Results

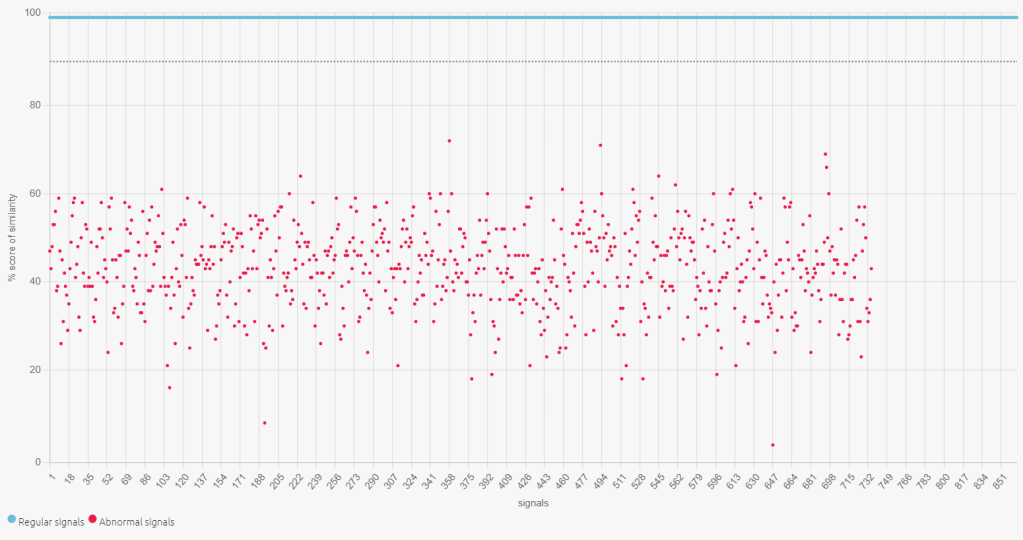

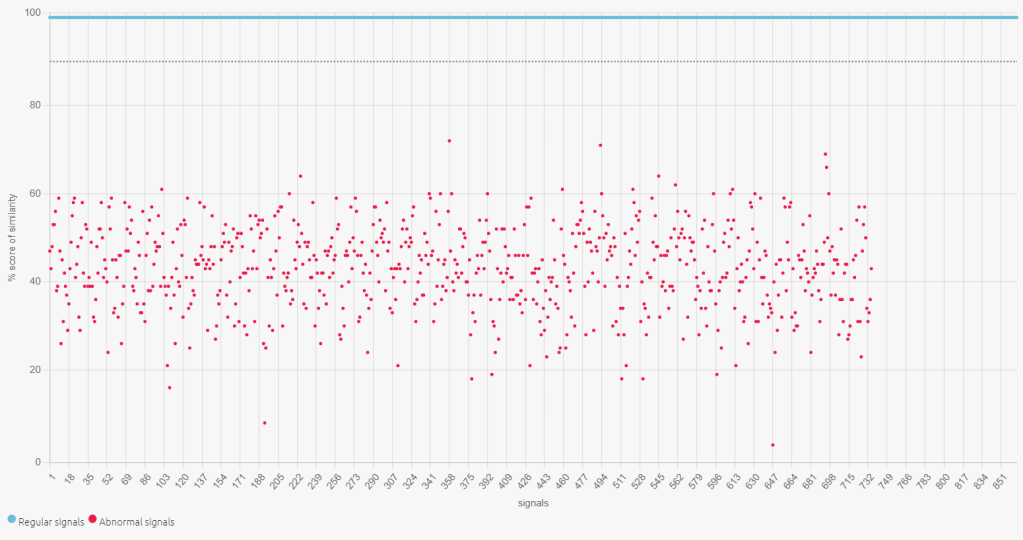

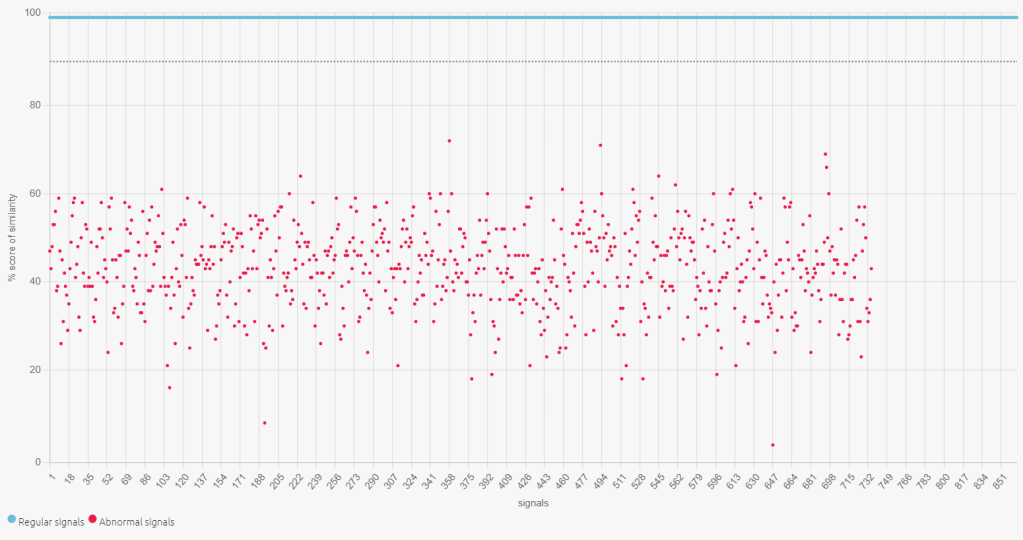

Anomaly detection:

99.67% accuracy, 4.0 KB RAM, 7.1 KB Flash

Blue points correspond to normal signals, red points to abnormal ones.

The signal numbers are on the abscissa and the confidence of the prediction is on the ordinate

Resources

Model created with NanoEdge AI Studio

A free AutoML software for adding AI to embedded projects, guiding users step by step to easily find the optimal AI model for their requirements.

The STM32 family of 32-bit microcontrollers based on the Arm Cortex®-M processor is designed to offer new degrees of freedom to MCU users. It offers products combining very high performance, real-time capabilities, digital signal processing, low-power / low-voltage operation, and connectivity, while maintaining full integration and ease of development.