SiC

Silicon Carbide

SiC: Silicon carbide for a more sustainable future.

STMicroelectronics introduced its first SiC diodes in 2004, after several years of research and development on silicon carbide technology. SiC MOSFETs were introduced in 2009 and entered mass production in 2014. Today, ST’s portfolio of medium- and high-voltage power products based on SiC technology is among the widest in the industry. ST is actively engaged in capacity expansion and development of a reliable and robust SiC supply chain able to meet demand growth and ensure continuity through extended longevity programs.

ST manufactures its SiC products to the highest standards to ensure reliable performance and efficiency gains for electric vehicle (EV) applications, solar inverters, energy storage, industrial motor drives, and power supplies. Our technology exceeds industrial and automotive application standards and is preparing to target more extreme aerospace applications.

ST Silicon Carbide Campus in Catania

ST recently announced a new high-volume 200 mm silicon carbide manufacturing facility for power devices and modules, as well as test and packaging, to be built in Catania. Combined with the SiC substrate manufacturing facility being readied on the same site, these facilities will form ST’s Silicon Carbide Campus.

Energy handling for a sustainable future

ST has been engaging in SiC R&D for over 25 years and has developed market leading SiC solutions, with full supply chain control.

The advantages of

SiC power devices

Power devices based on silicon carbide offer various key benefits over conventional silicon devices. Their higher voltage and higher frequency capabilities allow greater system efficiency, faster switching, lower losses, and better thermal management. Ultimately, SiC devices allow smaller and lighter power designs featuring higher power density.

SiC-based power devices can operate at up to 200°C junction temperature (limited only by the package), which reduces cooling requirements and allows more compact, more reliable, and more robust solutions. Existing designs can incorporate the performance and efficiency benefits of SiC devices without major changes, allowing fast development turnaround while keeping the BOM to a minimum.

SiC for electric mobility

SiC power devices find application in critical power systems inside electric vehicles, including traction inverters, on-board chargers and in the DC/DC conversion stage. They also provide significant efficiency gains in charging stations. With respect to their silicon-based counterparts, SiC devices offer the following advantages.

SiC for industrial power supplies and motor drives

SiC devices benefit industrial applications from motors and robots to various other factory automation systems, as well as in power supplies for servers and solar energy conversion systems. For industrial contexts, SiC devices can deliver the following benefits with respect to silicon-based devices.

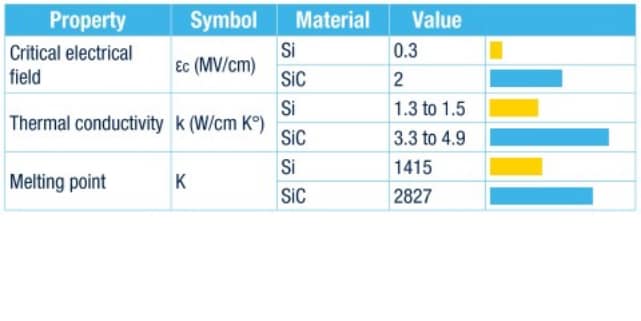

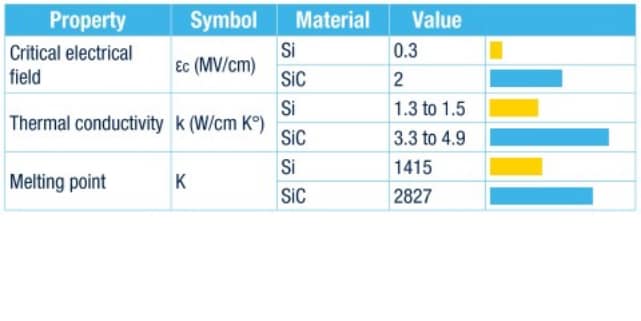

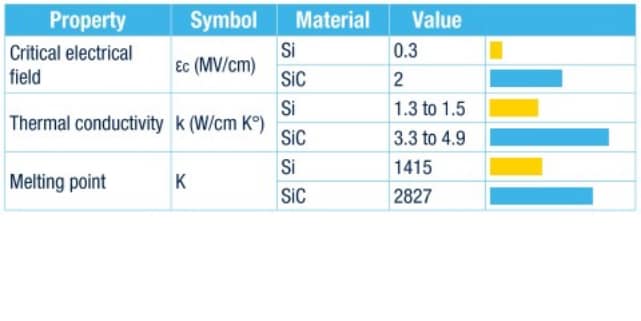

A performance comparison:

SiC versus Si technology

Silicon carbide is a wide-bandgap material that exhibits many intrinsic advantages over conventional silicon.

Learn more about

silicon carbide

Benefits of using ST's wide bandgap technology

Get a true feedback about which application types and conditions it makes sense to use SiC MOSFETs rather than traditional silicon devices in terms of performance and cost-effectiveness.

On-board chargers in electric vehicles

Discover how we can help you move your OBC design to a higher power class and provide the BEV or PHEV owner with an improved EV experience through shorter charging times.

EV traction inverter design challenges

We investigate the role of an EV's traction inverter, the electrical specifications required for its operation, the design challenges engineers face when developing them, and the impact wide bandgap (WBG) devices are having on their design.