Estimating torque and rotor temperature for improved motor performance

Using AI to extrapolate torque and rotor temperature values to improve motor performance.

Artificial Intelligence (AI) helps improve efficiency in various domains but also to unleash new features such as extrapolation to estimate values in order to optimize performance without having to add hardware components. Being able to have strong estimators for the torque and rotor temperature helps manufacture motors with less material and enables more efficient control strategies to ensure the motor is working at its maximum capability.

Approach

The goal was to estimate the torque and rotor temperature using only available information (motor speed, coolant temperature, voltages, etc.).

We created two sub datasets, one for estimating the torque and the other for the rotor temperature.

Using NanoEdge AI Studio, we then created two Extrapolation projects capable of estimating the torque and rotor temperature based on these inputs.

Sensor

Data

Signal length 10 (multi-sensors)

Data rate 2 Hz

Results

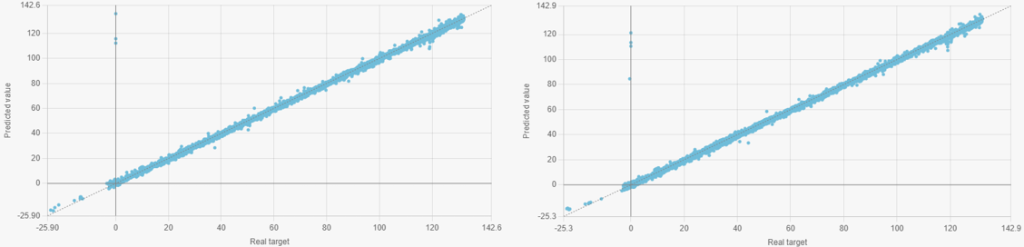

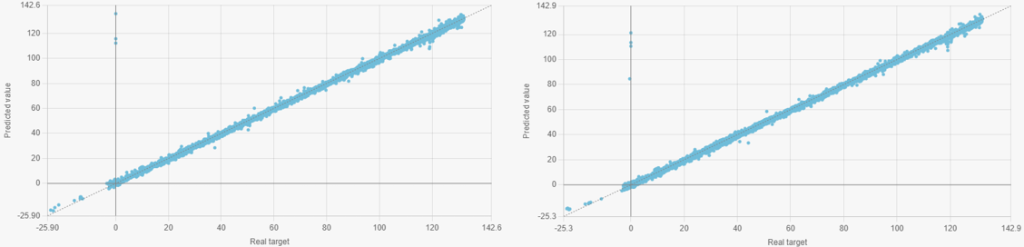

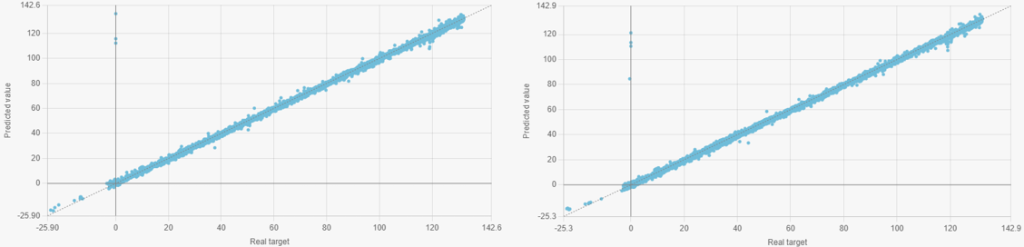

Torque extrapolation (left):

98.77% accuracy, 0.1 Kbytes of RAM, 0.3 Kbytes of Flash memory

Rotor temperature extrapolation (right):

98.81% accuracy, 0.1 Kbytes of RAM, 0.3 Kbytes of Flash memory

Resources

Model created with NanoEdge AI Studio

A free AutoML software for adding AI to embedded projects, guiding users step by step to easily find the optimal AI model for their requirements.

The STM32 family of 32-bit microcontrollers based on the Arm Cortex®-M processor is designed to offer new degrees of freedom to MCU users. It offers products combining very high performance, real-time capabilities, digital signal processing, low-power / low-voltage operation, and connectivity, while maintaining full integration and ease of development.