Monitoring and classification of fan-coil systems, like HVAC units, is crucial for predictive maintenance, performance optimization and energy efficiency.

Sensors and machine learning techniques are used in this field for applications like anomaly detection, predictive modeling, classification and regression analysis.

This is where edge AI comes in. At sensor level it can help in saving power while monitoring the status of the fan.

This use case will show you an example of implementation of fan coil monitoring using the ST MEMS sensors in the STWIN.box board.

Application principle

The classification is based on the motor vibration intensity, detected by the accelerometer part of the ISM330DHCX IMU (inertial measurement unit) available in the STWIN.box board.

Approach

Three classes are recognized by the Machine Learning Core (MLC) configuration of the ISM330DHCX: still, low vibration, high vibration.

The accelerometer data rate is set at 6667 Hz, and the full scale at 16 g.

The three classes are recognized by the decision tree running in the ISM330DHCX MLC.

Sensor

ISM330DHCX is an inertial measurement unit (IMU) with Machine Learning Core, Finite State Machine, and digital outputs for industrial applications.

The sensor is included in the STWIN.box board, a development kit for prototyping and testing industrial sensing applications in IoT contexts, such as condition monitoring and predictive maintenance.

Dataset and model

Dataset Three classes: still, low vibration, high vibration.

The accelerometer data rate is set at 6667 Hz, and the full scale at 16 g.

Model The model has been trained with a dataset of around 740 seconds, equally balanced in the three classes.

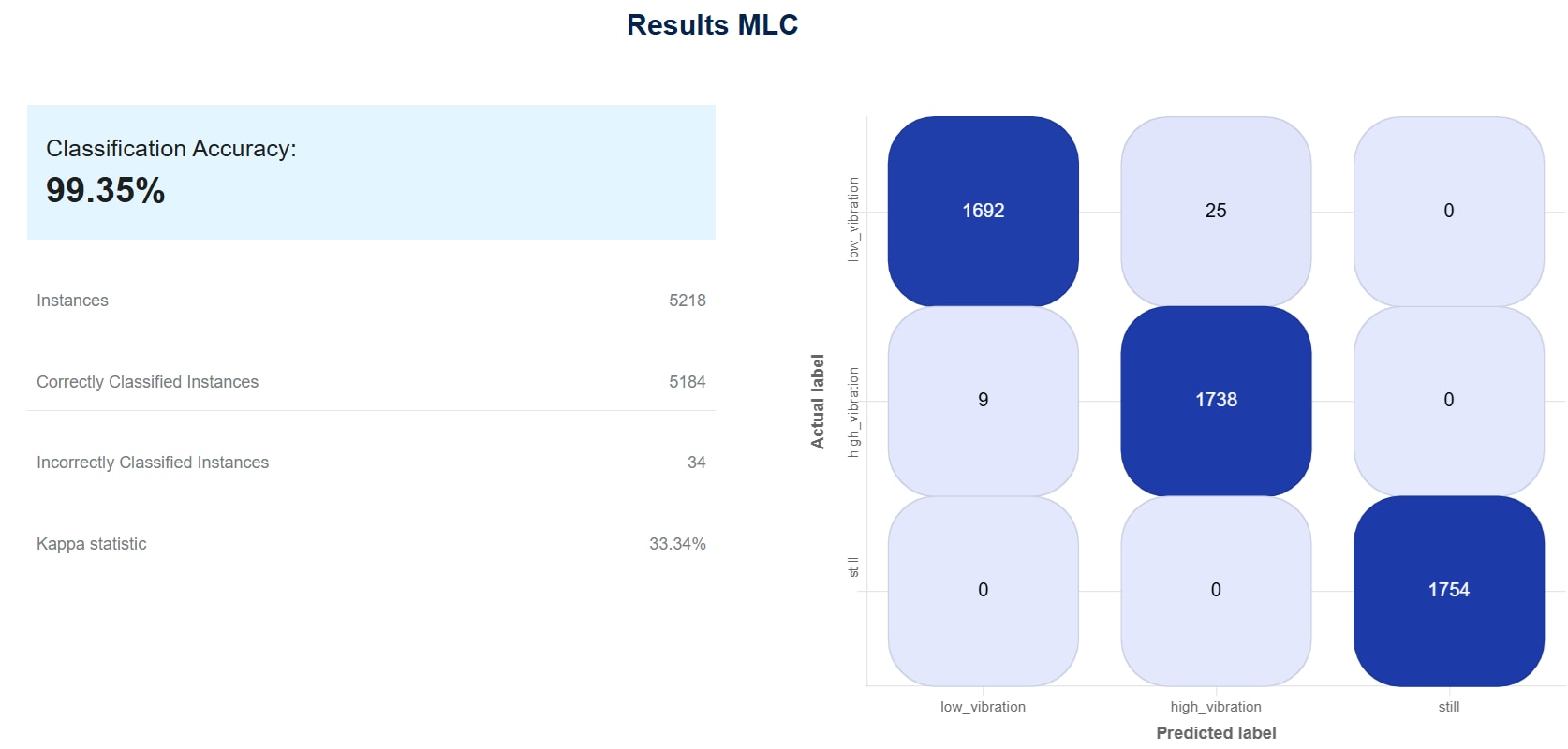

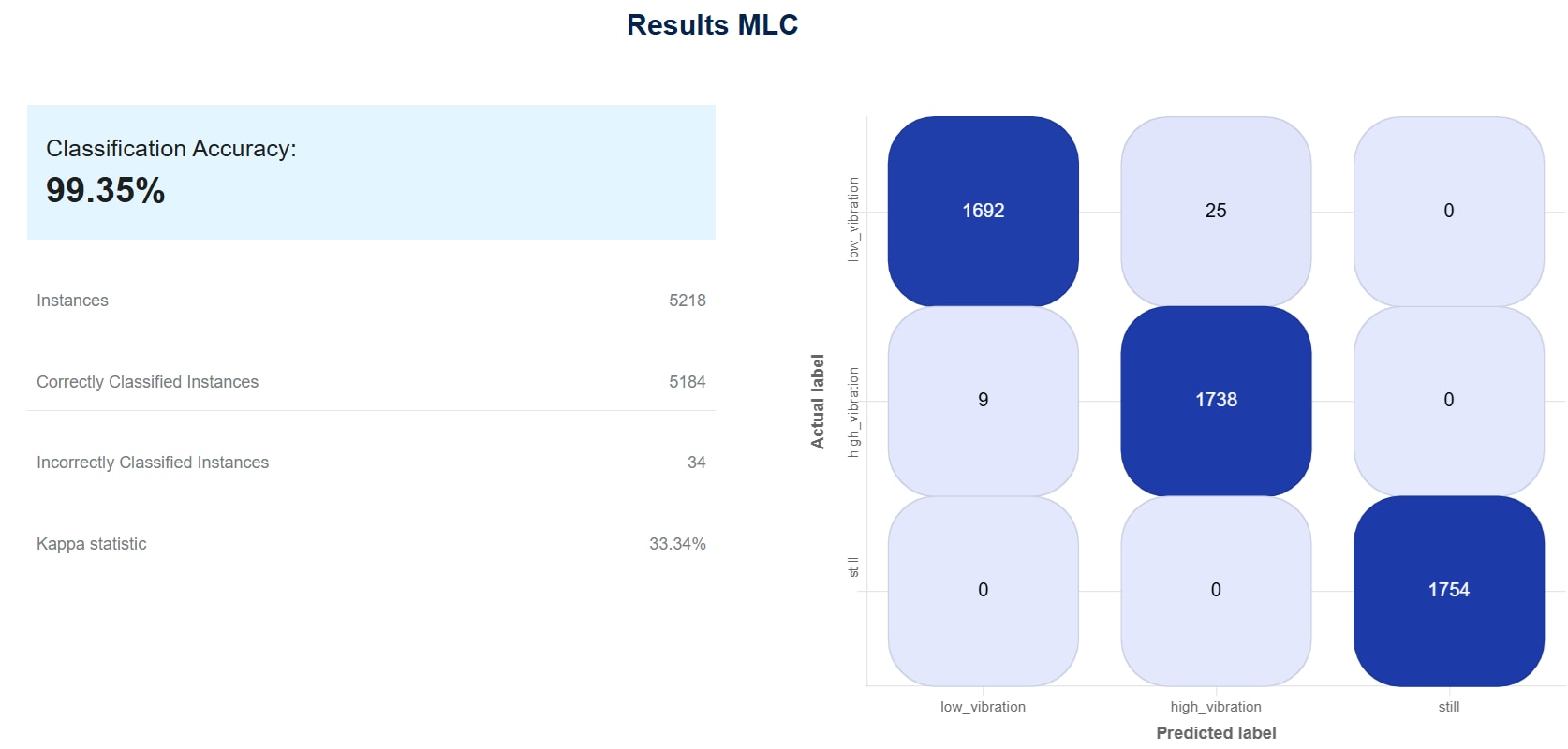

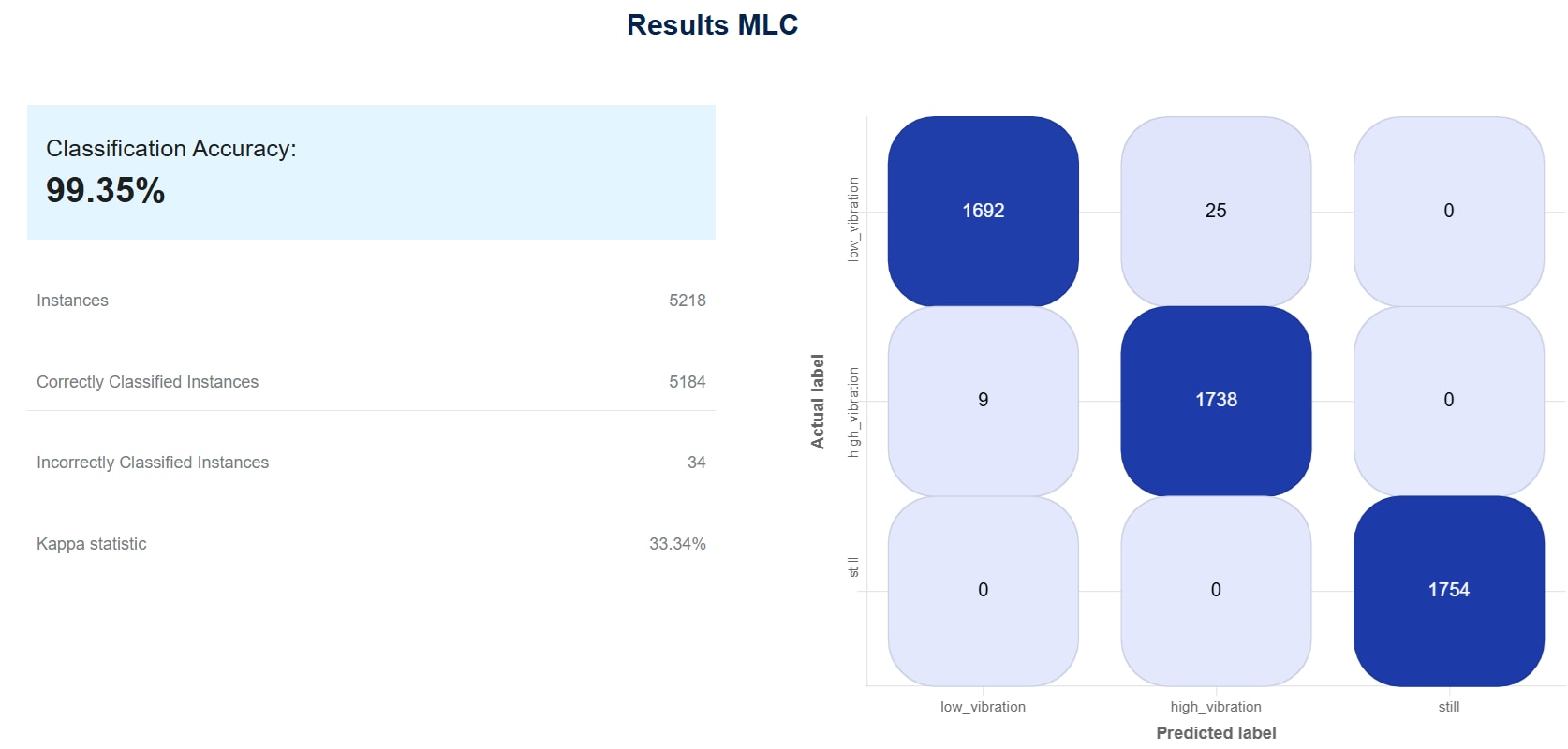

Results

The resulting decision tree model shows a 99.35% accuracy.

Easily recreate this use-case with the following resources:

- Open the use case with ST AIoT Craft

- Clone the project into your workspace, so that you can retrain in-sensor AI to work for other machinery such as motors or pumps.

- To use this example, make sure the board is firmly affixed to the front side of the fan, that is, the side that is pushing the air out. For accurate classification, the board's buttons should be facing outward (away from the fan), and the side with the USB port should face toward the ground.

Additional resources:

Author: Michele FERRAINA | Last update: February, 2025

Resources

Optimized with ST AIoT Craft

ST AIoT Craft enables the development of IoT solutions using in-sensor AI and ST components. It allows profiling decision tree algorithms within the machine learning core of ST MEMS sensors and deploying sensor-to-cloud solutions.

Most suitable for ISM330DHCX

The ISM330DHCX is a system-in-package featuring a high-performance 3D digital accelerometer and 3D digital gyroscope tailored for Industry 4.0 applications. It also features an MLC (Machine Learning Core) to embed machine learning algorithms inside the sensor.