Today's market requires high-performance solutions that meet stringent requirement for energy saving, compactness, and reliability as well as lower system costs in home appliances and low-/medium-power motor drive applications as well as in HVAC units, servo motors and other high-power industrial drives.

STMicroelectronics has developed the SLLIMM (Small Low-Loss intelligent molded module) family of compact, high-efficiency, dual in-line intelligent power modules (IPM) with optional extra features for addressing these needs.

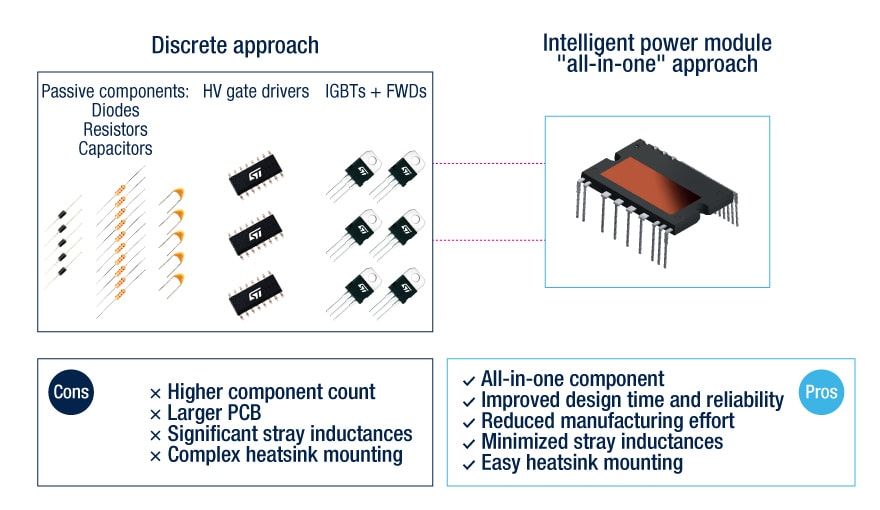

Advantages of intelligent power modules vs discrete-based inverters

Motor control applications usually share the same topology based on a three-phase inverter, which is used to convert static frequency and voltage into variable one.

In a simplified manner, a three-phase inverter consists of six switches, gate drivers, a control unit, and a signal conditioning circuit. For certain power ranges, a heatsink mounted on a power stage is required. The typical discrete approach for motor drive designs offers high flexibility, but has several drawbacks: more components, larger PCB significant stray inductance, and complex heatsink mounting.

Instead, the use of an intelligent power module overcomes these limits, since it replaces the 3-phase inverter configuration with an integrated solution, improving the design time and reliability, reducing manufacturing cost and efforts, minimizing stray inductances and facilitating heatsink mounting.

SLLIMM intelligent power modules provide a high-integration level that means simplified circuit design, reduced bill of materials, lower weight, and improved reliability. Available with different options in terms of packages (fully molded and direct bonded copper) and leads (through-hole and SMD), these IPMs combine six power switches (planar and/or trench IGBT, planar and/or super-junction MOSFET) and drivers in a 3-phase inverter configuration ensuring the best compromise between conduction and switching energies with outstanding robustness and EMI behavior.

ST offers strong technical support and a comprehensive ecosystem (online simulator, evaluation boards, and documentation) to help designers in developing their applications.

Applications

Thanks to a very large product portfolio combining different package options and ST’s best-in-class technologies, the SLLIMM family addresses a wide range of industrial applications:

- Air conditioners

(window/wall/portable) - Dishwashers

- Dryers

- Induction stovetops

- Kitchen hoods

- Refrigerators and freezers

- Washing machines

- AC Motor Drives

- Servo Motor Drives

- PMSM / BLDC

Motor control fans - Pumps and

compressors

- Commercial

indoor/outdoor

HVAC units - Central

indoor/outdoor

HVAC units

Product types

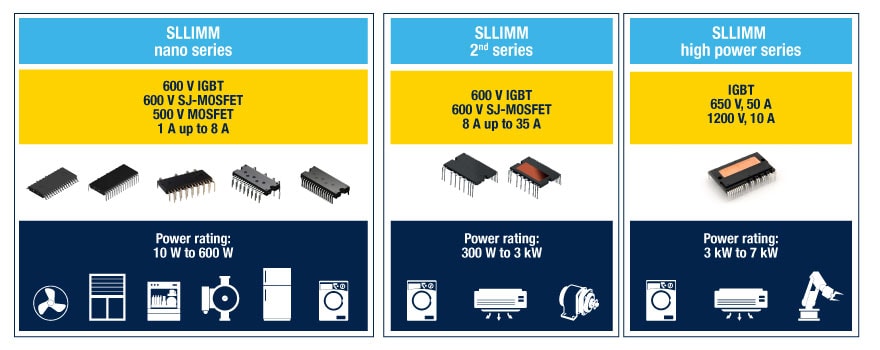

This series, including SLLIMM nano and SLLIMM nano 2nd series, combines six switches (IGBT or high voltage MOSFET) driven by three half-bridge high-voltage gate drivers.

These very compact IPMs are available in different full-molded packages: surface mount (SMD) and through-hole (in line and zig-zag) options and with a current capability from 1 to 8 A.

The SLLIMM nano family is tailored for home appliances such as roller shutters, fridges, dishwashers, and washing machines as well as pumps, fans, and motor drives working up to 20 kHz in hard-switching circuitries in a range up to 600 W.

SLLIMM 2nd series

This series is designed using an internal configuration featuring one high-side and one low-side driver, and includes improved trench gate field-stop IGBTs and super-junction MOSFETs as switching options, with a current capability from 8 to 35 A. These IPMs are available in full-molded and top-side cooling direct bonded copper (DBC) packaging options suitable for low-to-medium and high-power applications respectively. The SLLIMM 2nd series enables high power efficiency in home appliances (washing machines, pumps, fans, and AC units) and motor drives working at up to 20 kHz in hard-switching circuitries from 300 W to 3 kW.

This is the new compact, powerful, dual-in-line series, which expands the existing SLLIMM IPMs in terms of breakdown voltage, current capability, and power range.

These IPMs integrate a complete inverter stage, including six short-circuit rugged IGBTs with freewheeling diodes, associated with high-side and low-side gate drivers in a single package. Built-in features for fault protection and temperature control are also included.

It’s mainly tailored for industrial applications such as HVAC, servo motors, general-purpose inverters (GPI), and industrial washing machines for power applications up to 7 kW.

Discover our portfolio

These features make the SLLIMM family ideal for enhancing the efficiency of 3-phase inverters for any motor drive operating up to 20 kHz in hard-switching circuitries and for an application power range from 10 W to 7 kW.

Benefits

- System integration and compactness

- Reduced bill of materials

- High efficiency and low power losses

- Extended power range up to 7 kW

- Increased thermal dissipation capabilities

- High reliability and robustness

- Pin-to-pin compatible with main industrial IPM competitors

eDesignSuite

eDesignSuite is a comprehensive set of easy-to-use design-aid utilities ready to help you streamline the system development process with a wide range of ST products.

Power Management Design Center

Thermal-electrical Simulators for Components

Signal Conditioning Design Tool

NFC/RFID Calculators

Power Supply Design Tool

LED Lighting Design Tool

Digital Power Workbench

Power Tree Designer

STPOWER Studio

PCB Thermal Simulator

AC Switches Simulator

Rectifier Diodes Simulator

Twister Sim

TVS Simulator

Estimate

Active Filters

Comparators

Low side Current Sensing

High side Current Sensing

NFC Inductance

UHF Link Budget